Final year project

Improving posture and gait of people with Parkinson's disease through the… [Read more]

A wearable device to improve posture and gait of people with Parkinson's disease.

Many people with Parkinson’s disease suffer from postural problems and issues with gait. These can not only be disruptive to daily life but can also increase the risk of falling. My product provides a discreet solution that aims to improve posture and gait through the use of vibrational feedback and cueing to ultimately improve the quality of life for Parkinson’s sufferers.

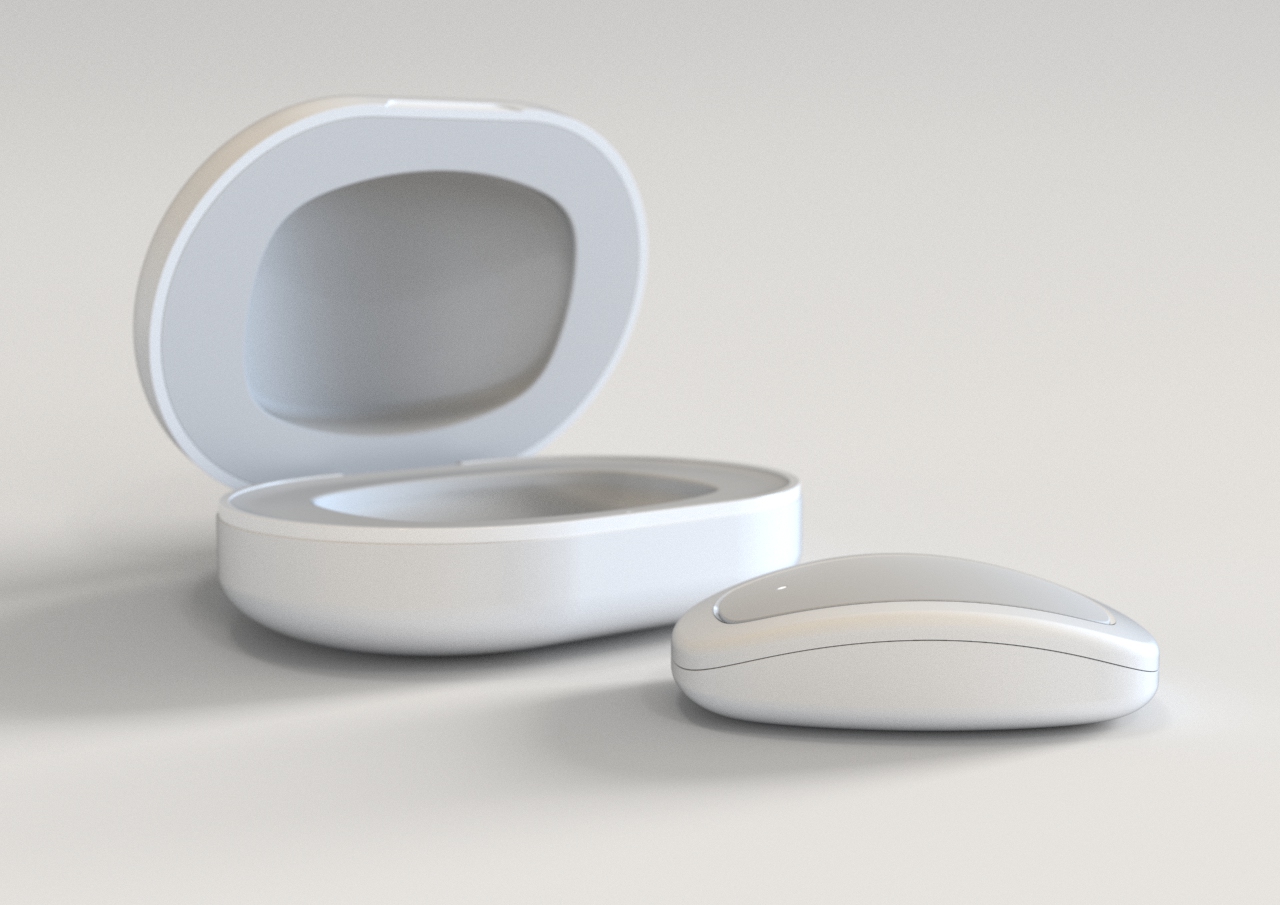

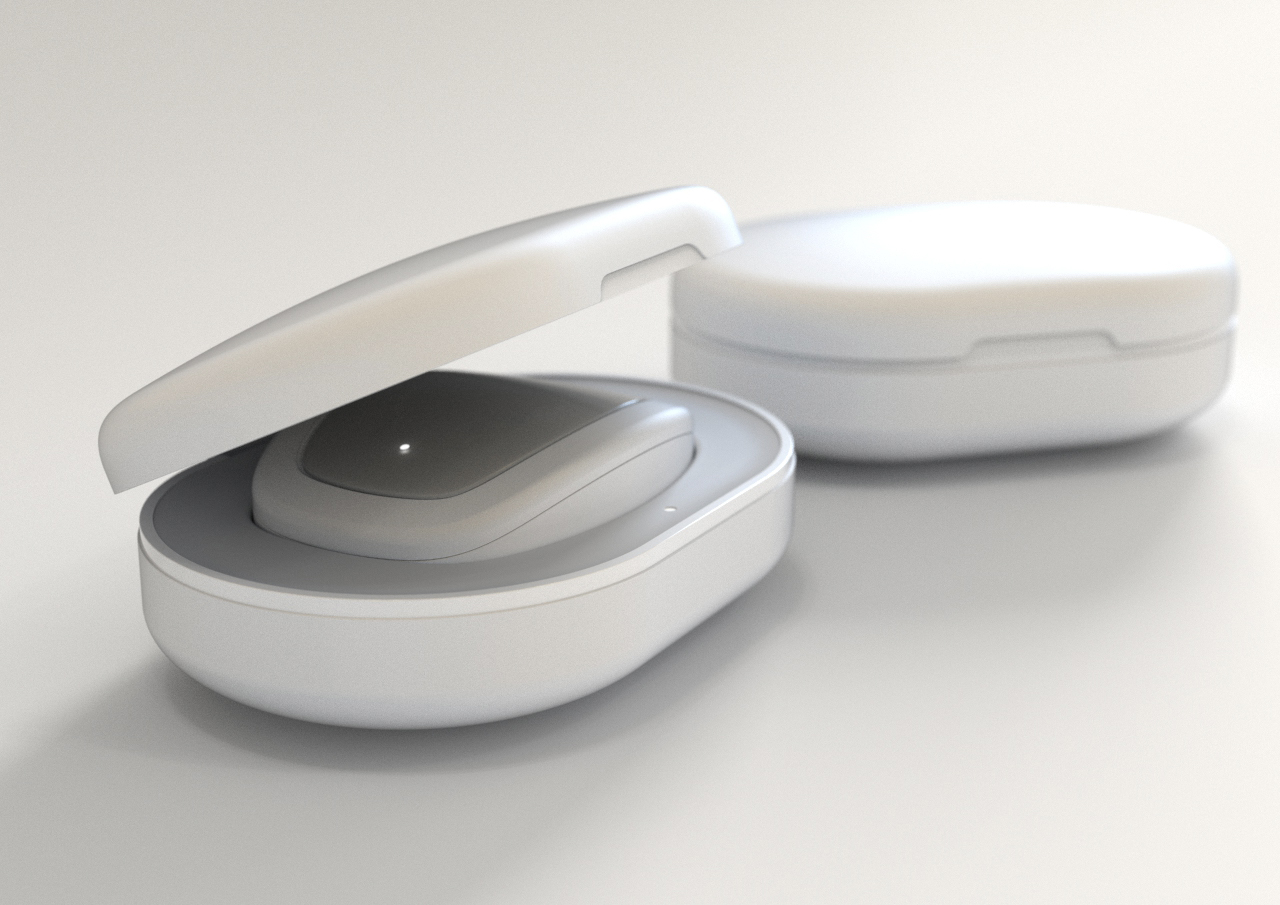

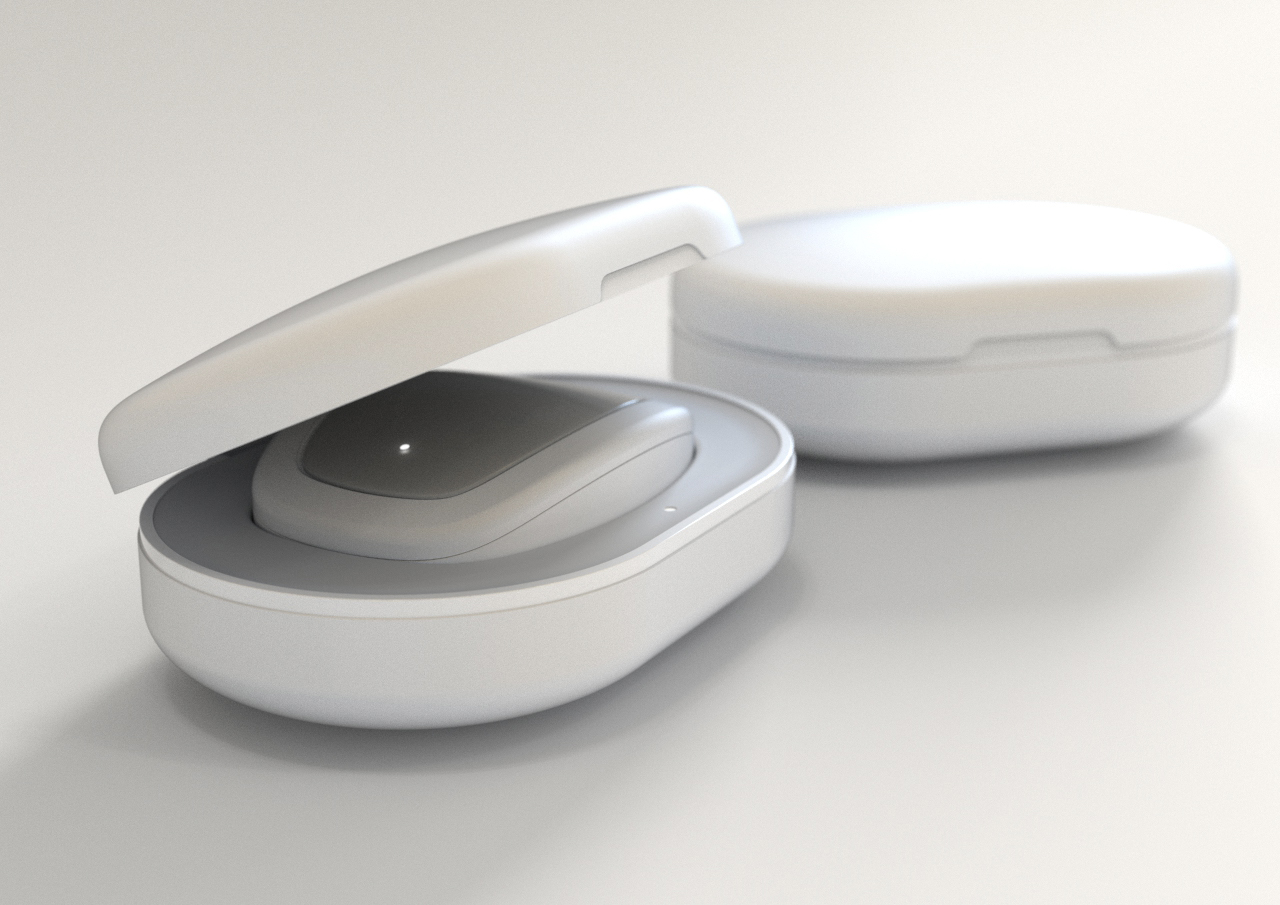

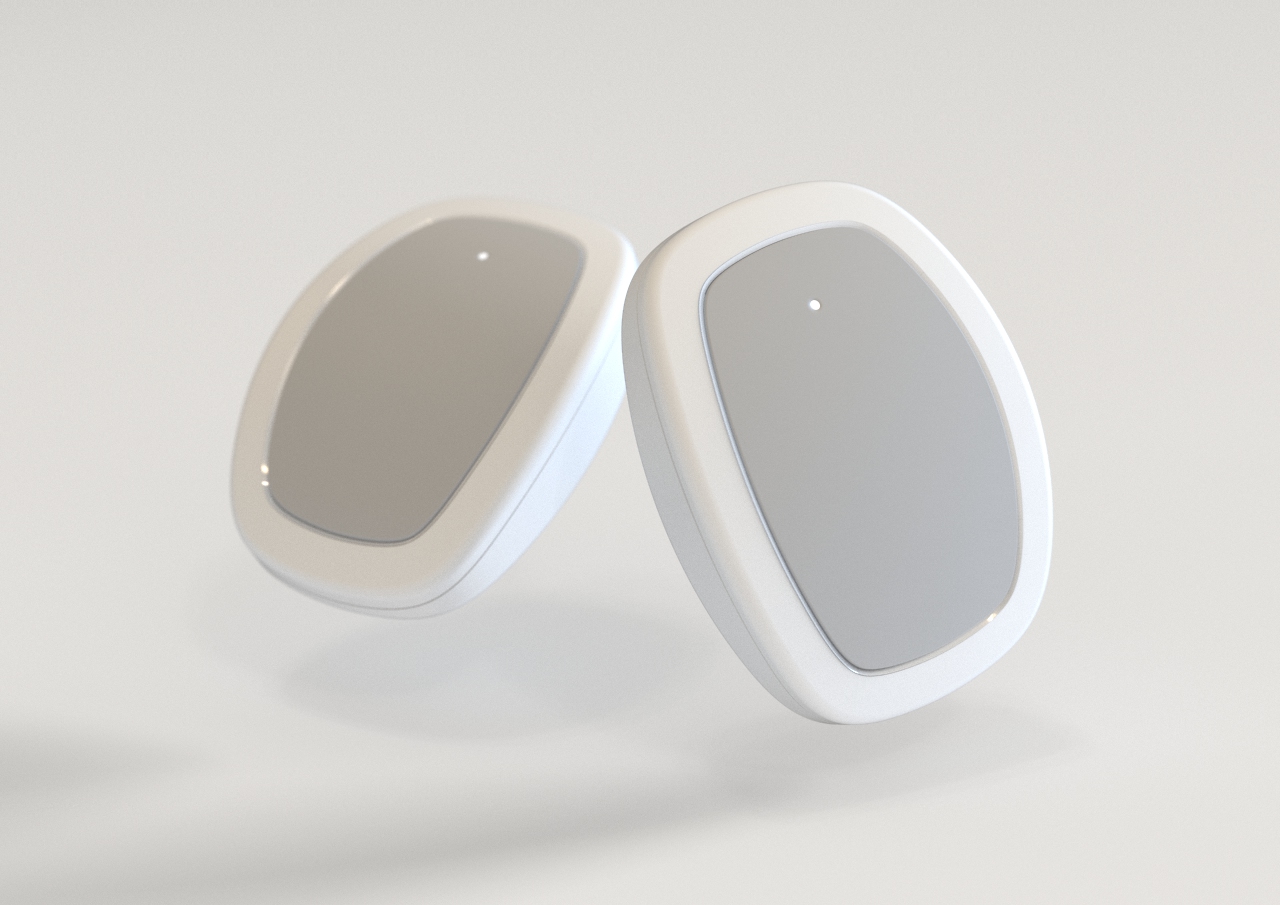

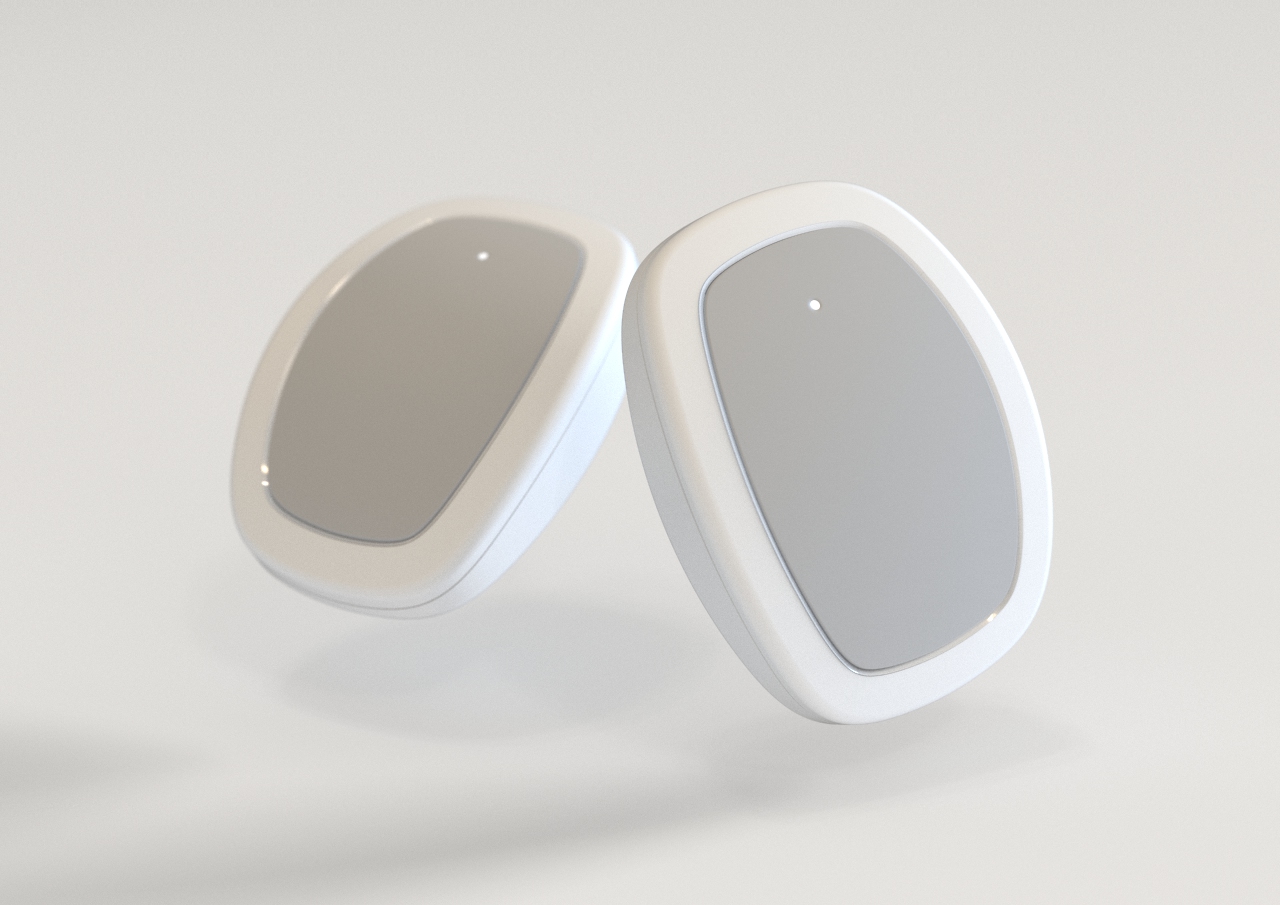

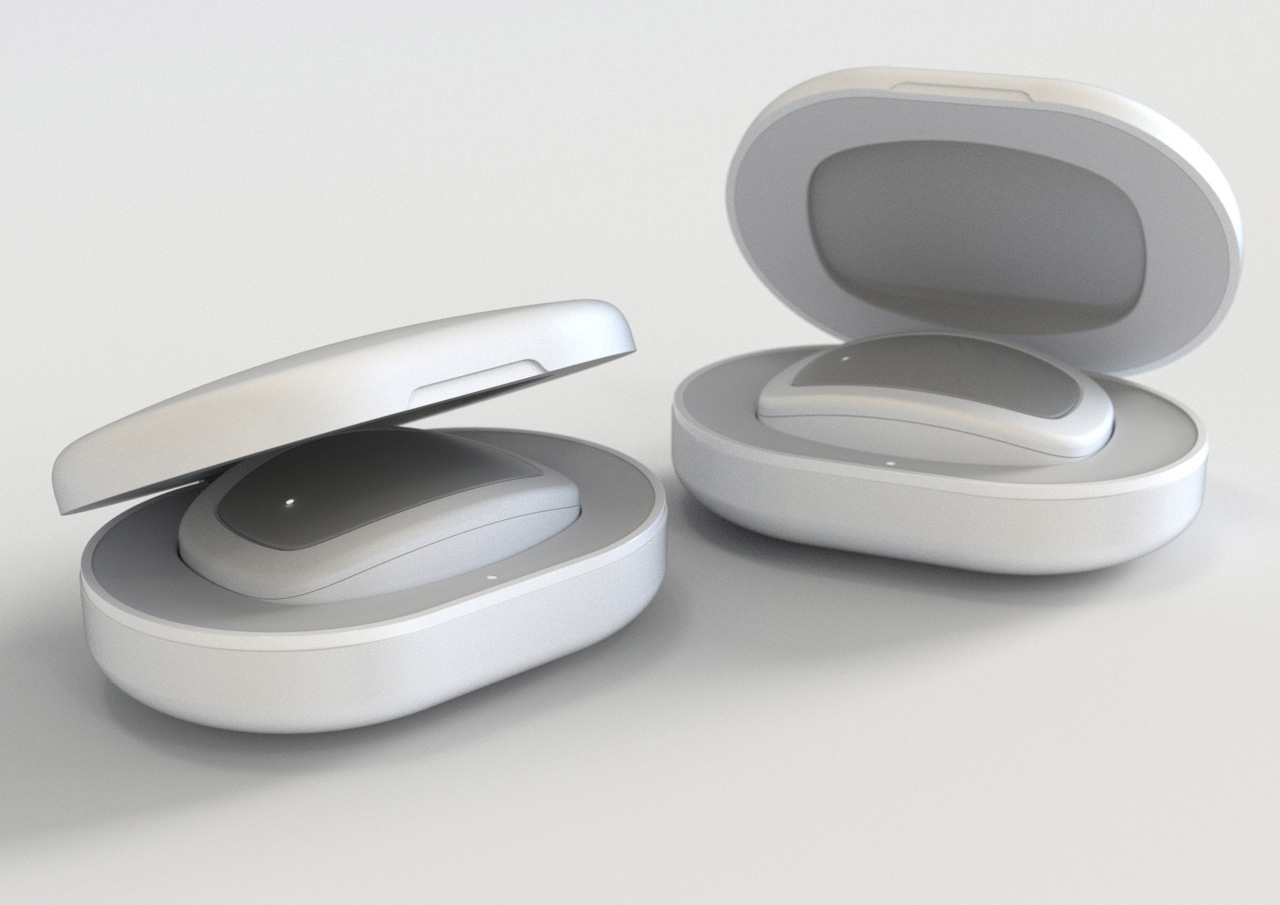

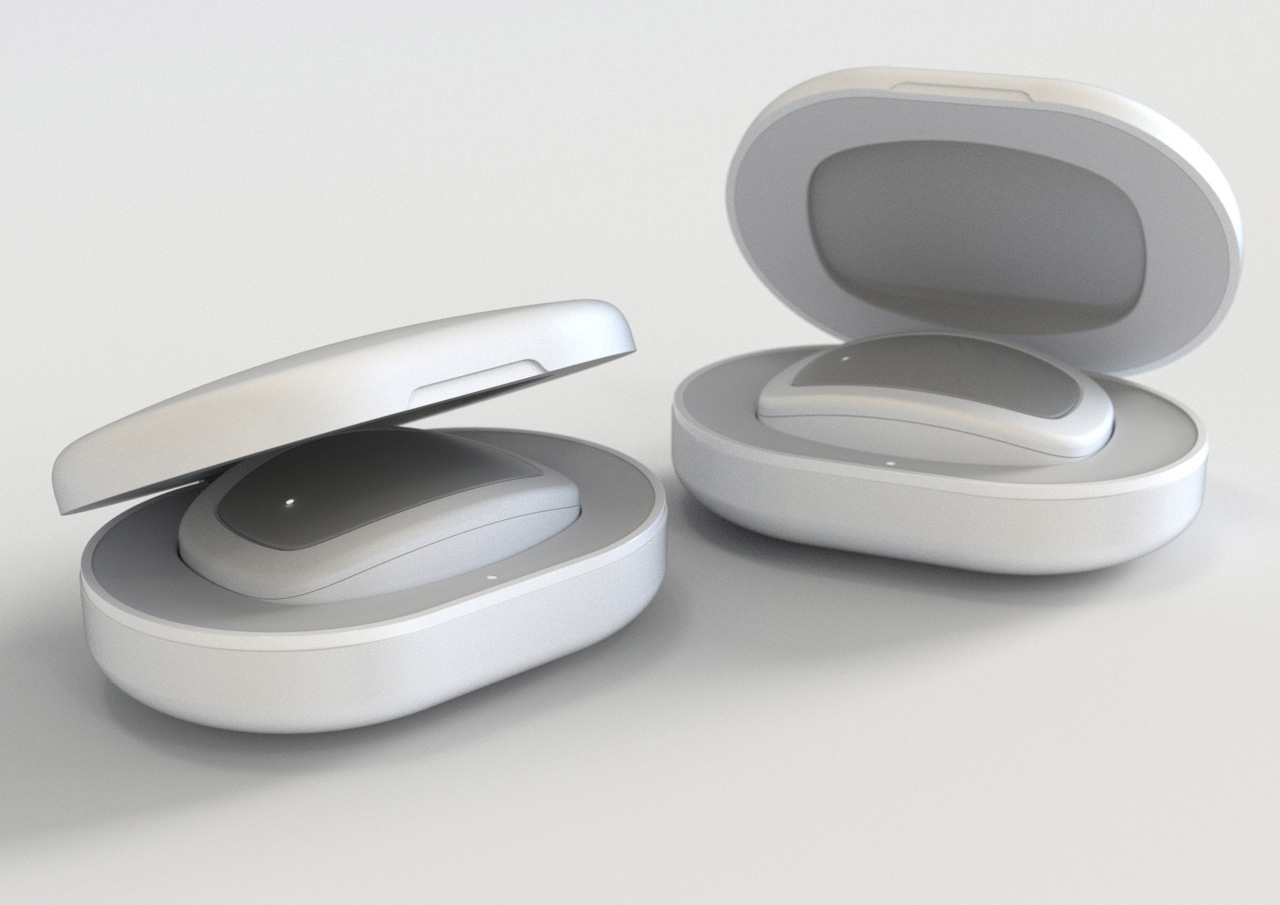

Discreet Design

Designed to be discreet and elegant to prevent the stigma associated with Parkinson’s disease and related medical devices. When not in use, the device is designed to be stored safely in the accompanying charging case.

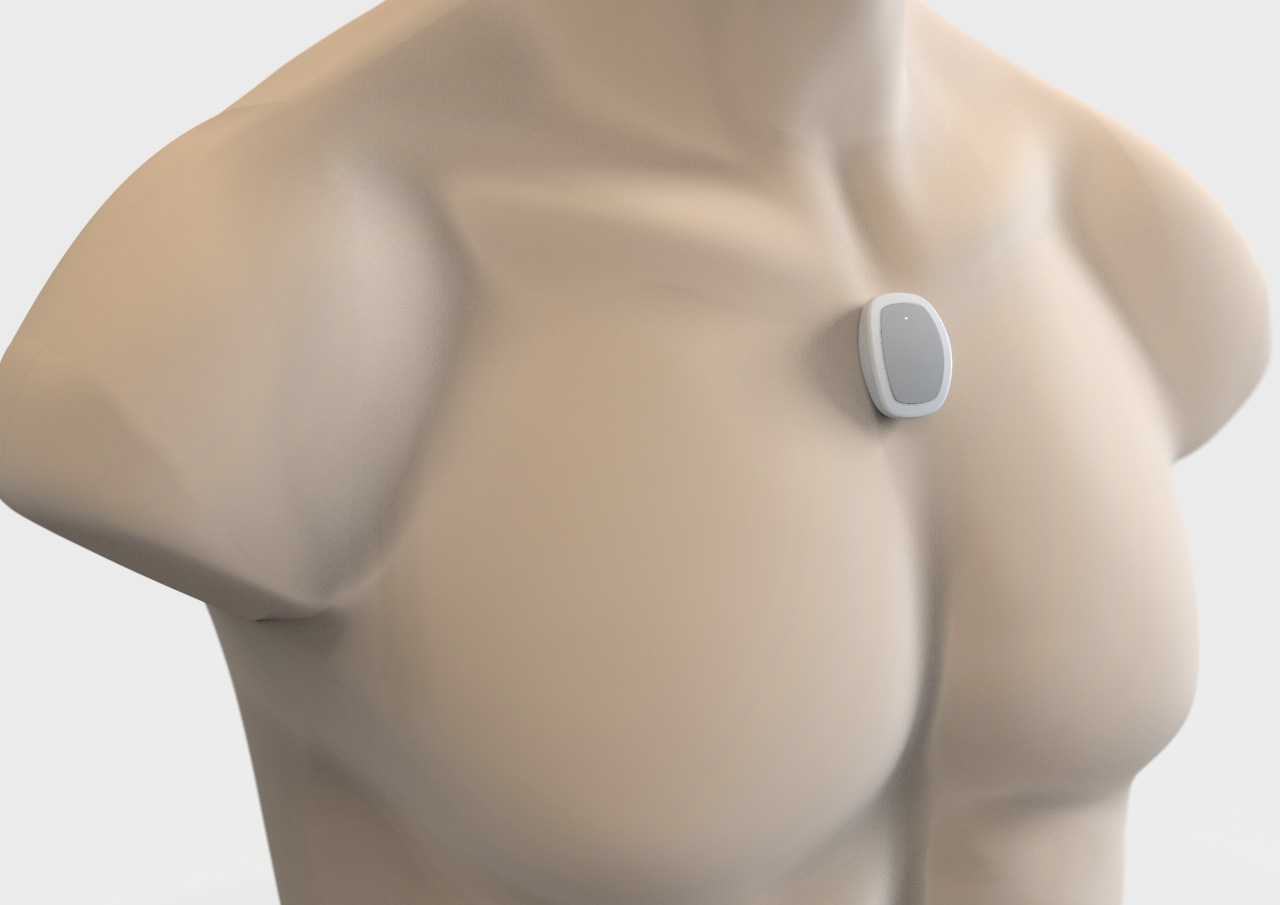

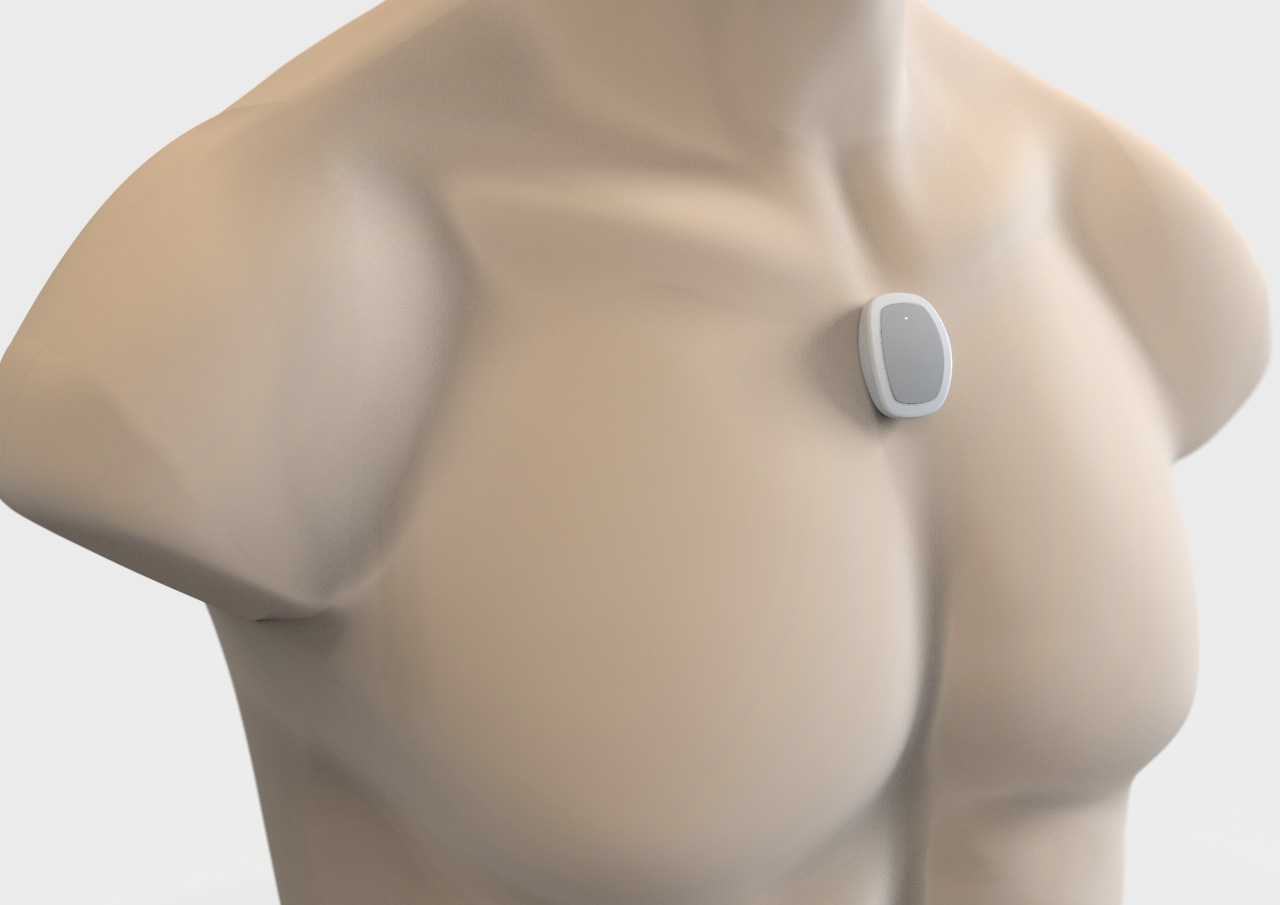

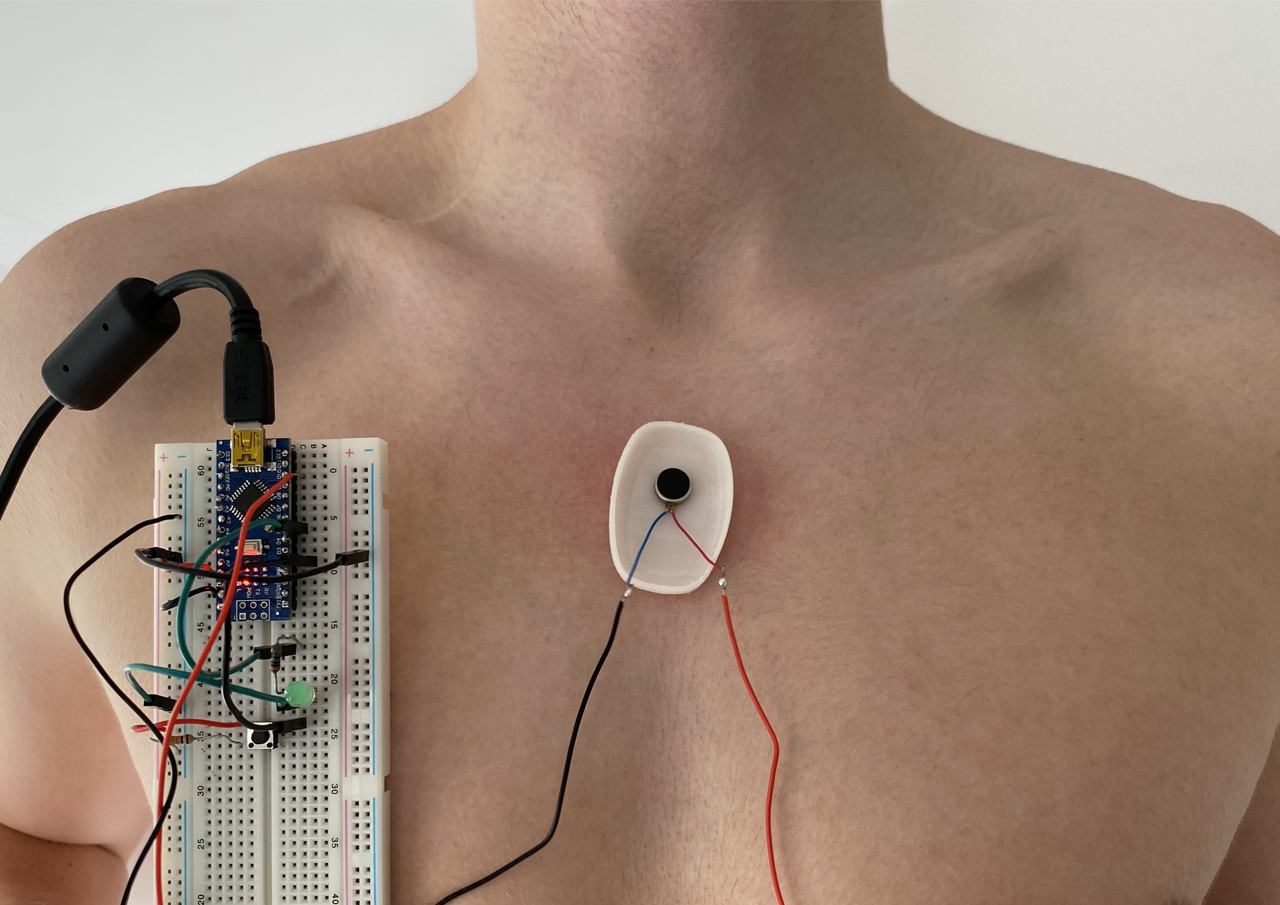

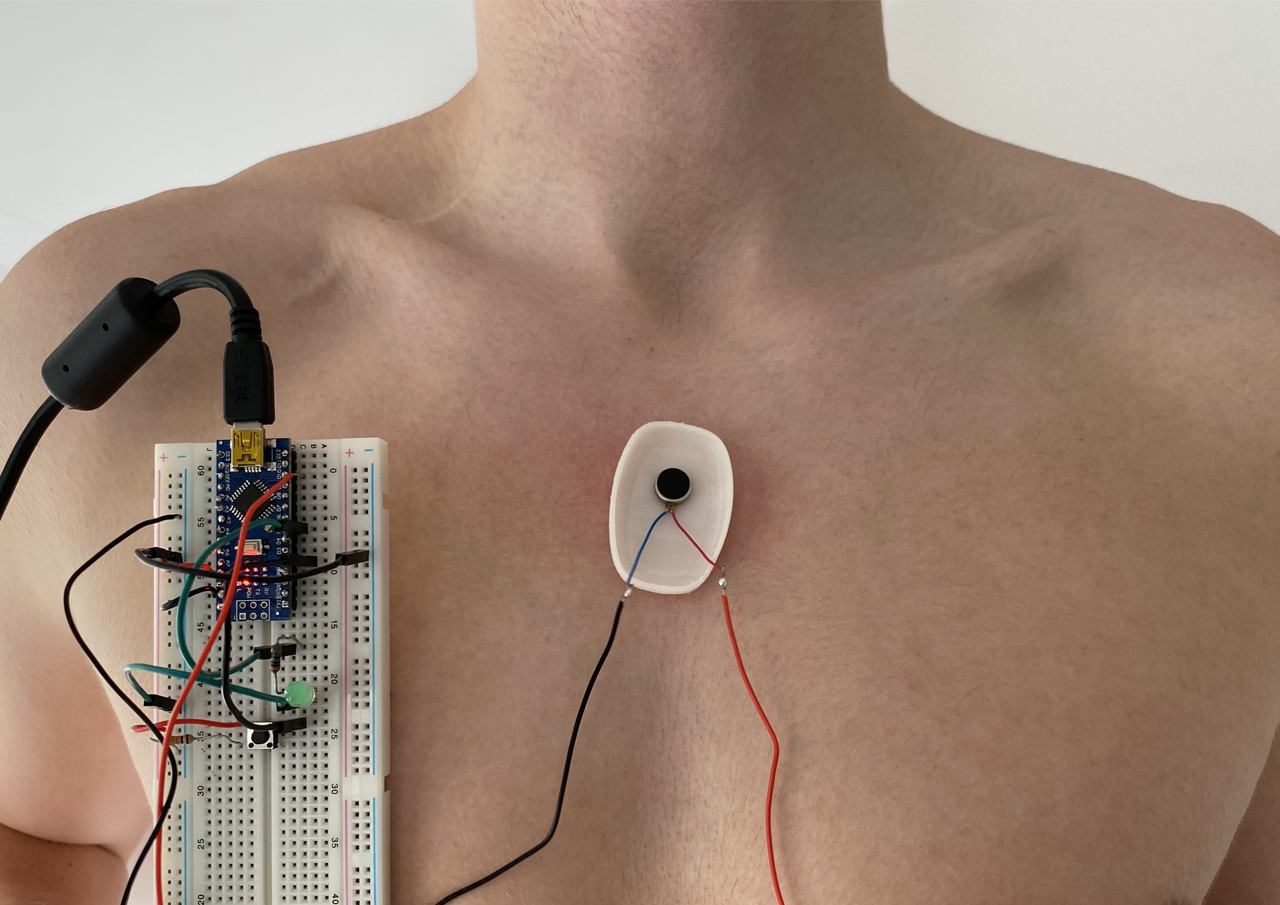

Device Positioning

The user attaches the device to the chest area using soft silicone gel adhesive pads. This allows for easy application, removal and operation of the device.

Simple Operation and Posture Detection

One simple tactile button allows easy operation for users with potentially limited dexterity.

The built-in accelerometer and gyroscope can accurately detect when the user’s posture deteriorates and provides a clear alert to the user via the haptic motor.

Vibrational Cueing

The device’s haptic motor is also used for cueing, providing a customisable tempo to which the user can match their walking pace in order to facilitate smooth movement and help prevent freezing of gait. The different cueing speeds can be altered to the user's preference in the smart app.

Electronic Prototyping

Electronic prototyping was used extensively to ensure proof of concept and test a variety of aspects of the design.

Lewie Brooks

A passionate and versatile product designer with a strong interest in the technical detail and viability of the final design solution.

During my time at Loughborough University and my year on placement at Rutland Plastics, I gained a range of design skills in CAD, Design for Manufacture, Electronics, Additive Manufacture and User Experience. All of my projects have enabled me to engage in practical hands-on design work to help create attractive, yet manufacturable, products with the users’ needs at the heart of the design. I’m now looking to immerse myself in an innovative and fast-paced environment with the opportunity to expand my skills and knowledge as a designer.

Final year project

Improving posture and gait of people with Parkinson's disease through the use of vibrational cueing and feedback.

Awards

'21 Diploma in Professional Studies

Work Experience

I completed a year-long placement at Rutland Plastics (a custom UK injection moulder) as a Design Engineer. During the year I was able to extensively build on my knowledge of design for manufacture, injection moulding and additive manufacture. I loved having the opportunity to be involved in project development from initial design to the finished physical product.