Final year project

Food Waste Prevention Stock Management Scanner. [Read more]

Iterative Prototyping Through FDM Printing

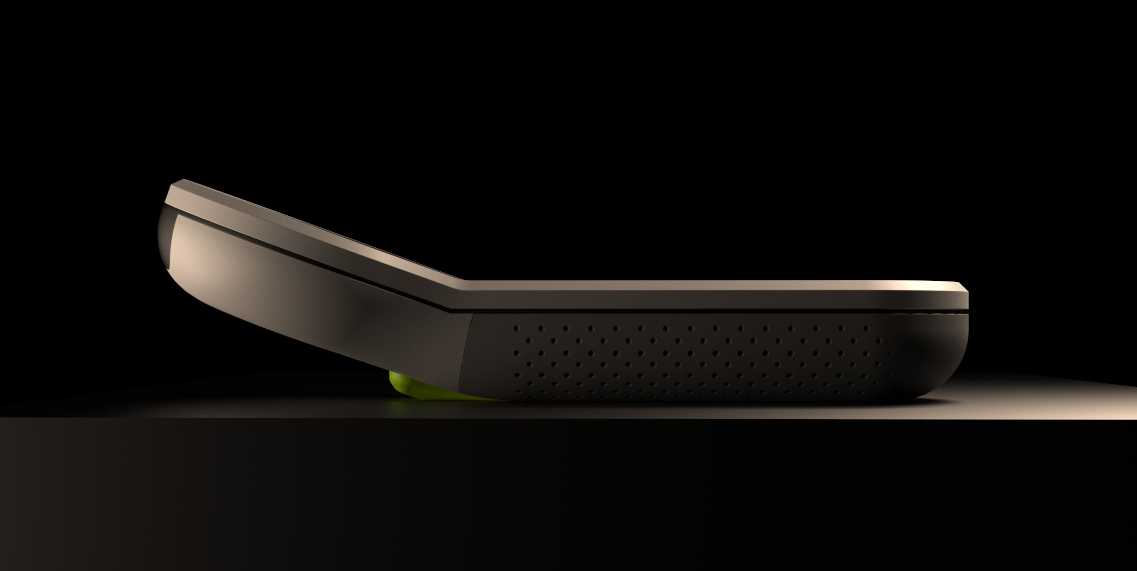

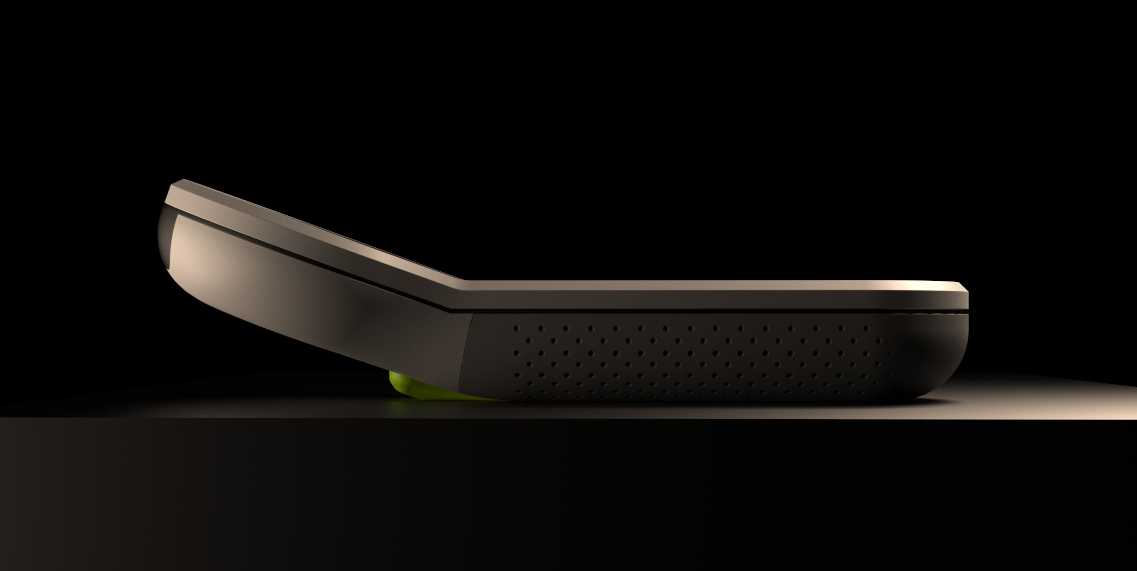

The design focuses on ergonomic comfort, achieved through iterative prototyping. Heavily focusing on the placement of the devices inputs and their ease of use, a simple yet precise user input system was crucial for the design.

Instant Feedback

With a display surrounded by the input dial, the user is able to simultaneously input and visualise the data allowing for speed and confidence of use.

Dock/Display

The dock allows for easy visual access to the data collected. This will alert kitchen staff on any actions that need to be taken. Using the scanners as controllers for the display allows for a streamlined product solution that keeps the barcode scanners out of the way in a busy kitchen.

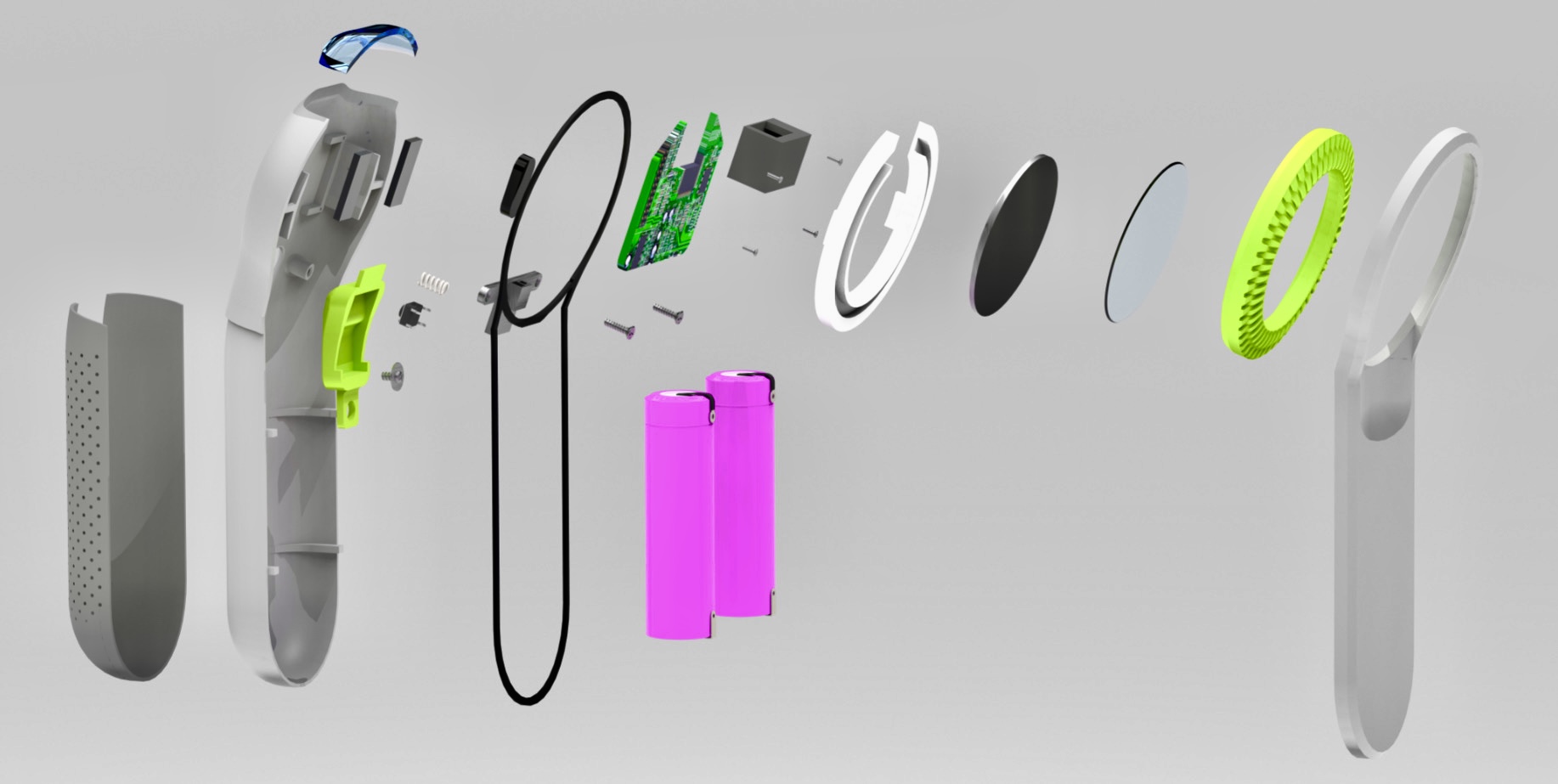

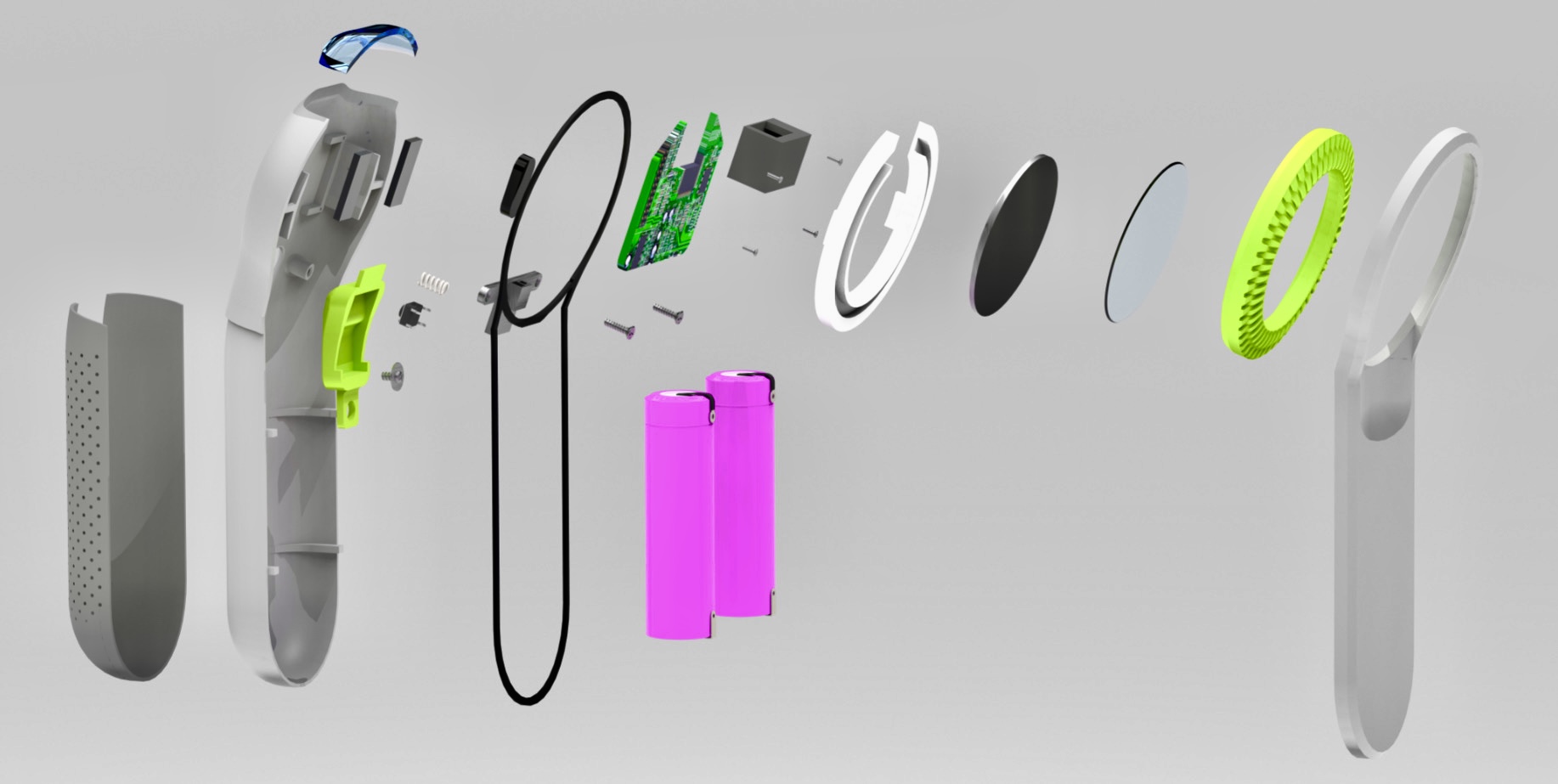

Design For Manufacture

Applying the knowledge gained when manufacturing mould tools and speaking to industry professionals ensuring manufacturability was key when finalising my design.

Balanced Design

The balanced symmetrical form allows for use in both hands. Through contact point testing and the application of ergonomic data, the inputs are accessible for users with any hand size.

Print In Place Locking Mechanism

Designing for additive has allowed me to approach my designs differently. Considering how mechanisms can be built into products from the initial design phase allows for innovative product solutions. This 'print in place' bike light holder contains a locking ratchet mechanism reducing the need for fittings when attaching the part to a bike.

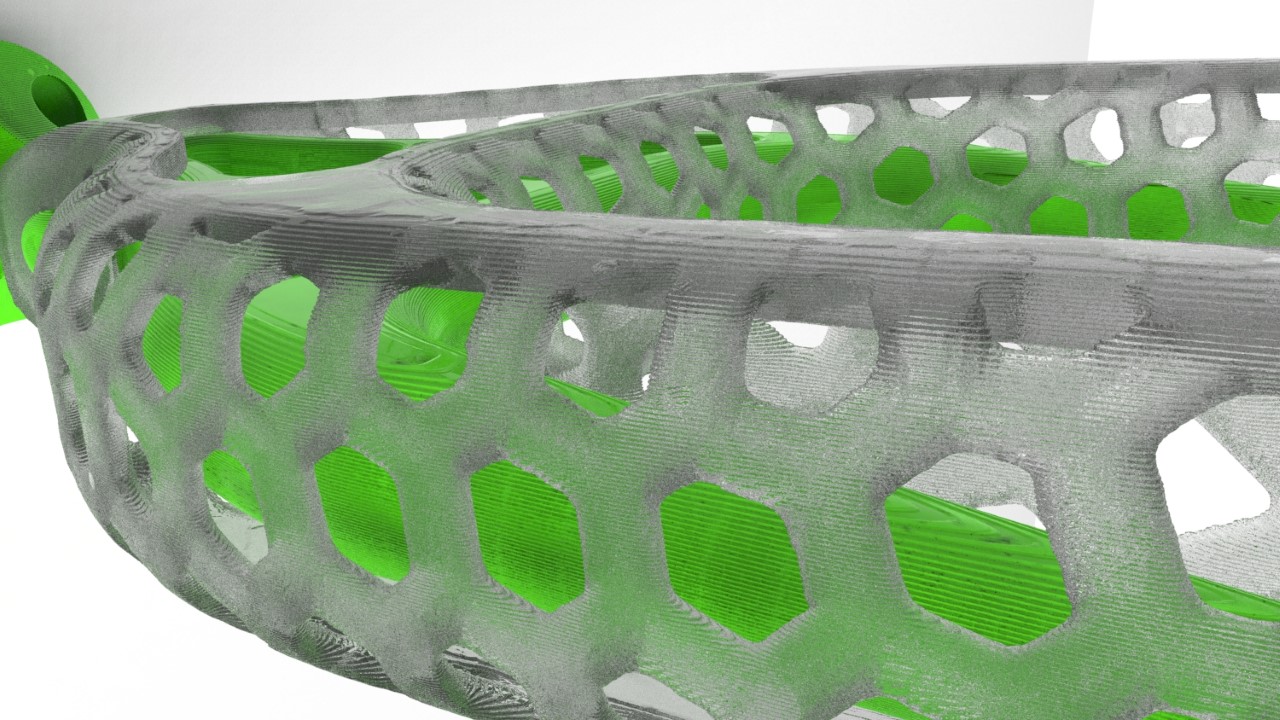

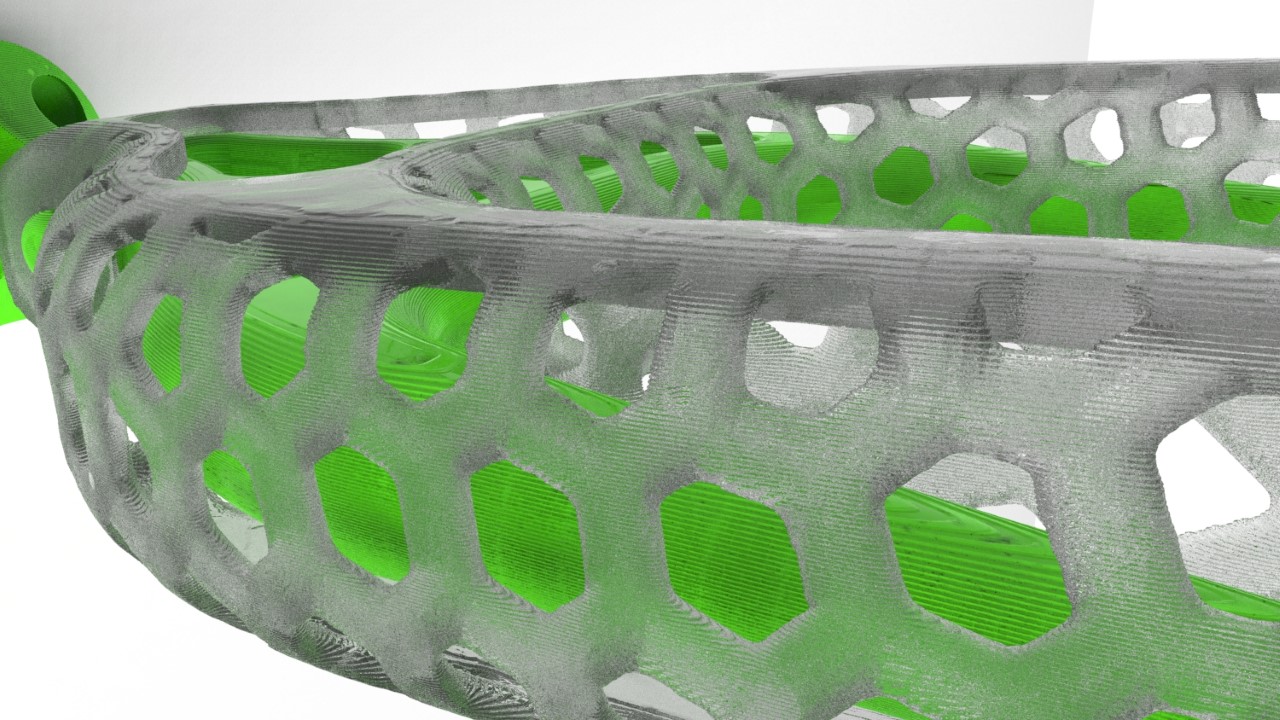

Voronoi Latticing

Looking further into 3D printing has led to explorations into new software and CAD approaches. Gaining experience on packages such as Ntopology and Gen3D has allowed me to build a strong understanding of latticing and generative design.

Julian Patient

A barcode scanner allowing for easy multi level data collection in active environments such as kitchens.

With restaurants needing to manage an ever-growing list of stock, my design provides an intelligent and user-focused solution. With a lack of barcode scanners intended for environment-specific data collection, this product and system aim to allow for streamlined and efficient stock data collection using familiar input methods.

With a 30% turnover of staff in the hospitality field and a tasking work environment, industrial kitchens often struggle to accurately collect stock levels. In active environments, where there is little time to struggle with complex keypads and touchscreens, this product provides a simple tactile solution using a familiar dial-based input. It allows for the user to quickly collect critical stock information such as quantity and expiry dates.

I focused on ease and speed of use in the design of this product and was able to consistently collect required stock information in under 2 seconds per stock type.

Having been introduced to 3D printing at Loughborough, I have been able to gain a good amount of experience using a wide variety of machines and additive technologies. Through experimentation into live hinges, 'print in place' mechanisms and explorations into wood-based 3D printing, this technology has now become a major part of my workflow.

In the future, I hope to work in the ever-growing field of additive manufacture and have a focus on additive design thinking.

Final year project

Food Waste Prevention Stock Management Scanner.

Awards

Diploma in Art and Design (Distinction)

Solidworks Professionally Certified - CSWP

Arkwright Engineering Scholarship