Final year project

Reducing the impact of Heat-Stress in the Construction industry through the… [Read more]

ThermMate - Thermoregulation device for Construction workers

Having worked in the construction industry in intense conditions, I understand the impacts our environments have on our health while doing intense physical work. Workers experience heat stress injuries and illness across the world every day, leading to hundreds of deaths each year. I wanted to create a product to inform, manage and monitor heat stress and the physical well-being of construction workers. The product provides workers with a cooling and heating element to combat early heat stress symptoms and thermal discomfort.

Technology and Electronics

Peltier cooling/heating technology is used alongside the circulation of air through the use of fans to maximise the cooling power. Internal components are shown above and have all been externally sourced. I have tested the concept through the use of a functional prototype made with Arduino.

User experience and interaction

I have tried to create an aesthetic that merges fluid with rugged design styles to suit my user's preferences. A simple but effective user experience has been developed through the use of manual controls and supporting mobile app. The user has full control and has the ability to personalise settings. This was developed through Adobe UX.

Environment

ThermMate is built to have the durability to withstand the harsh environment of a building site. Using a series of environmental and health sensors the device will be able to analyse the risk of heat stress and provide warnings and advice when the user is at risk. Material and manufacture considerations were refined to create a durable and reliable product.

In Use

The product cools specific thermal sensitive areas on the neck to achieve an intense cooling sensation, mitigating the effects of heat stress. Extensive modelling, testing and development have been carried out to ensure an ergonomic design was achieved.

S-Cycle - Design Week Project

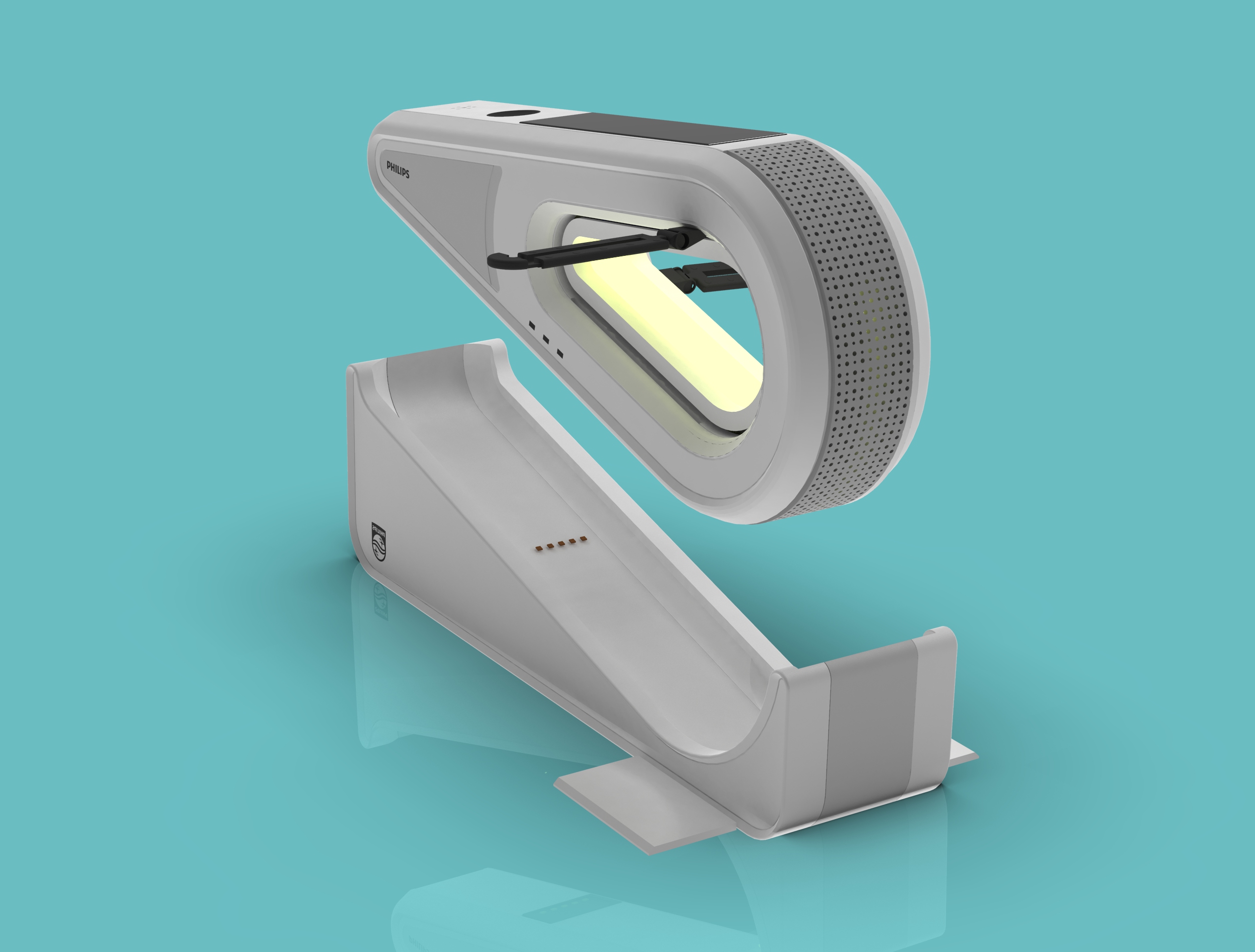

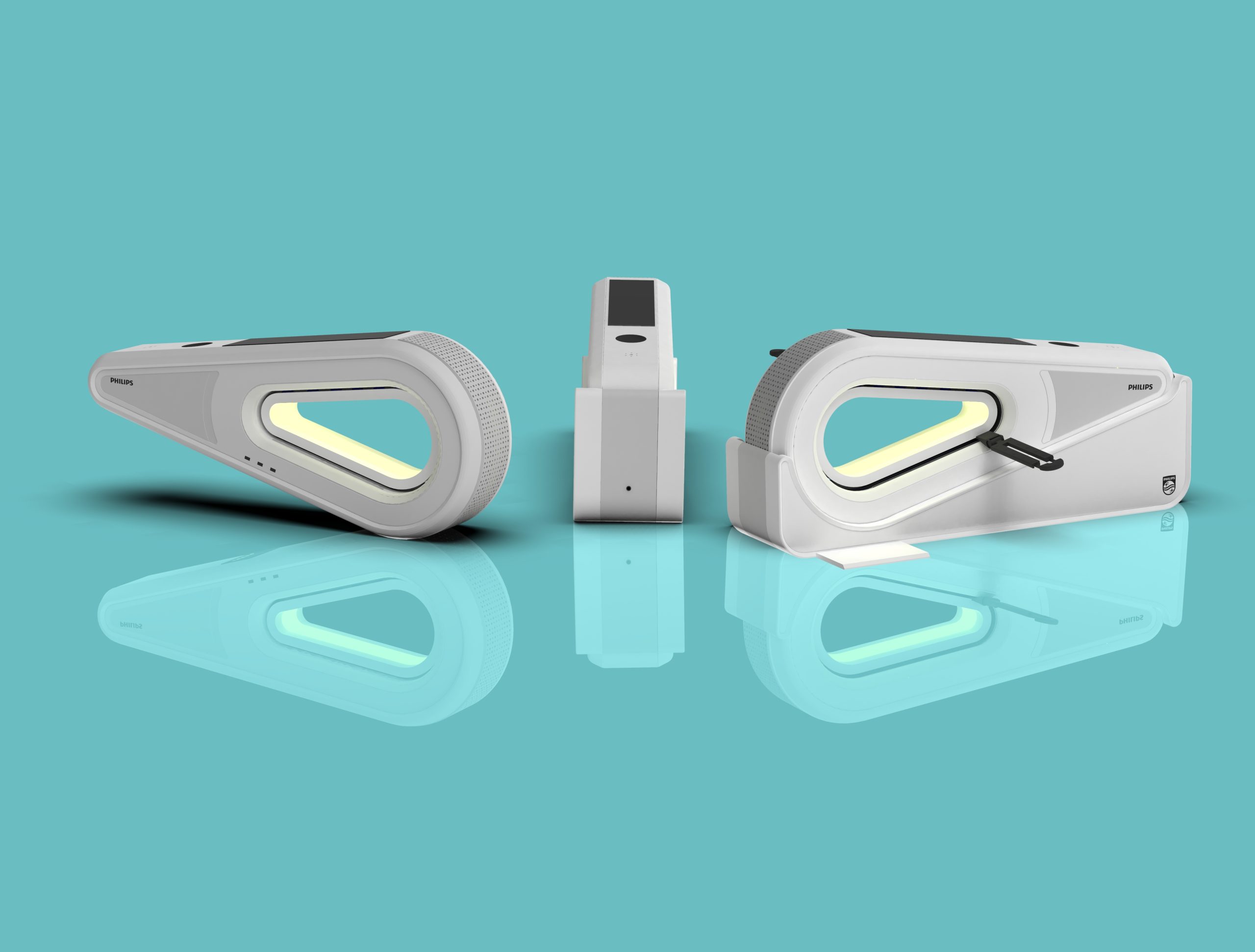

For my design week project, I created the “Philips S-cycle” is a product designed to enhance the fitness of people working from or spending lots of time at home. The product works through the use of a magnetic resistance system connected to a driving chain, providing the user with a cycling motion with variable resistance. This was an enjoyable yet challenging project due to the strict time limit.

S-Cycle - Design Week Project

The product allows friends and colleagues to work out together and stay connected through voice chat and competitive games. The multi-functional product can be alternatively used as a Sunlight lamp and cooling/heating fan to maximise the comfort and productivity in the user's workspace. This project involved lots of rapid prototyping and development to achieve a feasible final product.

Jack Lord

Design for me is a method of solving problems through the application of science, technology and out the box thinking all combined through the design of innovative products.

Over my time at Loughborough I have been able to refine my design skills from this has all accumulated to one large final year project that allows me to showcase my skills. Over the course of the project, I developed my product from an initial problem to a manufacturable product through the use of Research, Sketching, Cad, Prototyping and many other design techniques.

Final year project

Reducing the impact of Heat-Stress in the Construction industry through the use of a Thermoregulation device.

Awards

2020 Diploma in Professional Study

Work Experience

My third year placement year was at a Design and Production company in Amsterdam. This was an amazing experience which gave me lots of responsibility in the company as I was the only designer there. I worked on many large and small scale projects from interiors to mass-produced products.

I have been a Freelance Graphic Designer since 2018, I have designed Advertisements, Logos and had inputs on websites for many companies. I was also heavily involved in the advertisements at the catering company I was employed at by helping create and advertise events.

I have also had a month of school internship at a bespoke furniture production company called Kaizen.