Final year project

A Toy that Helps Introduce Children to Mechanics [Read more]

A Toy that Helps Introduce Children to Mechanics

I chose to focus my main project on trying to create something that would help introduce mechanical principles to children between the ages of 8 and 12. I felt there were plenty of toys that focused on programming and other educational areas but almost nothing that taught mechanical fundamentals such as gear ratios and forces. My product fills this gap, providing a system of mechanical components that allow a child to experiment and design working mechanisms, completing set tasks, such as building a car or a paper plane launcher.

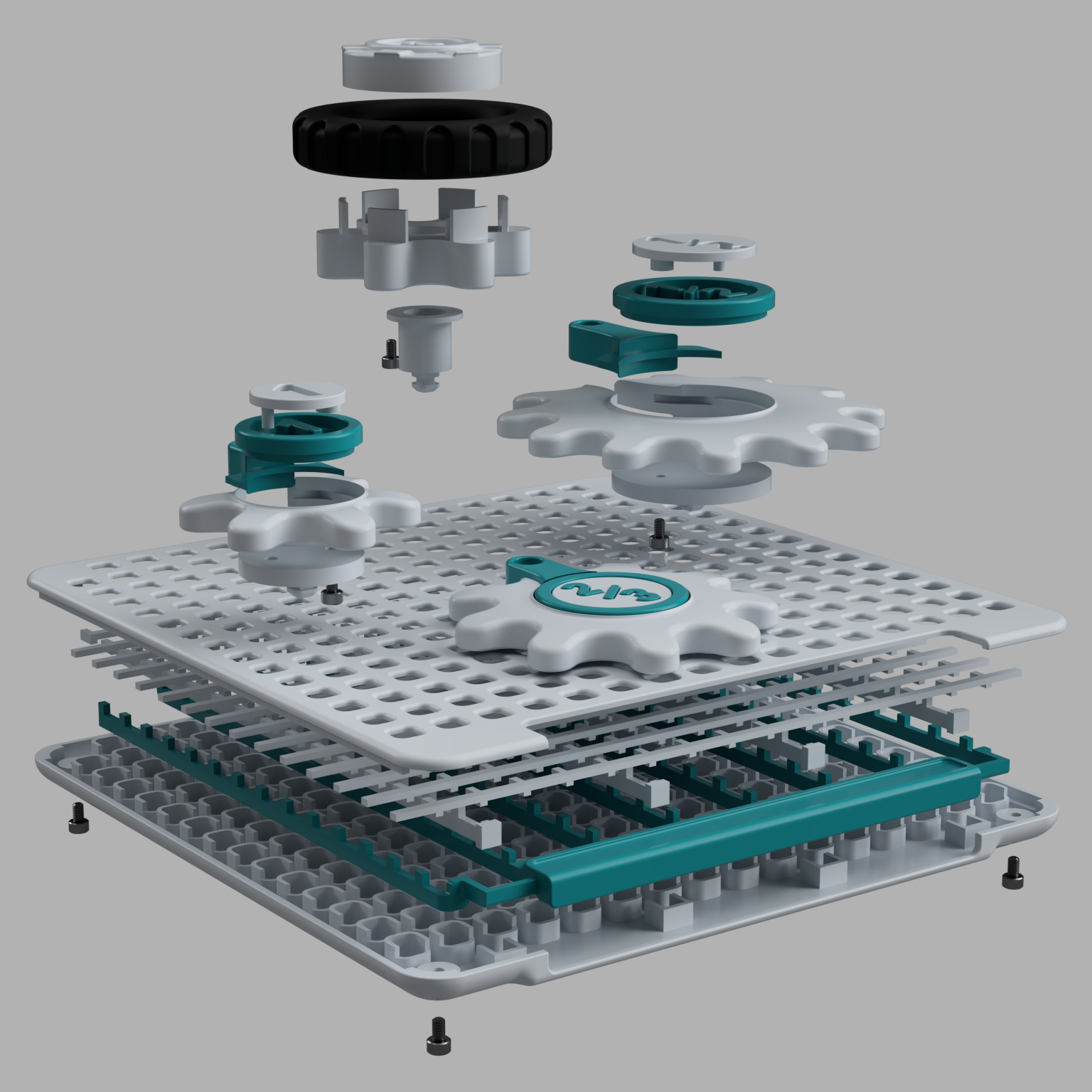

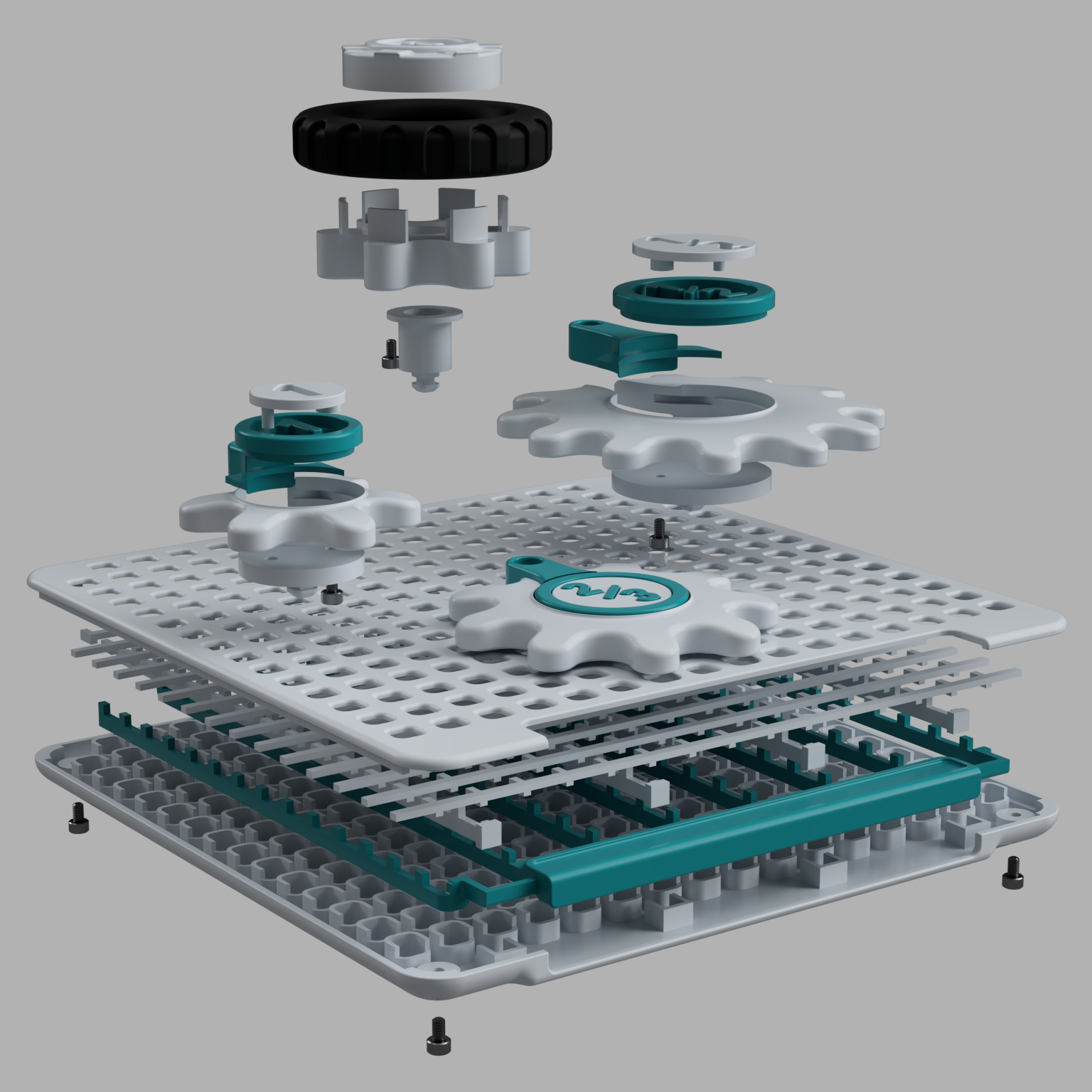

Mechanical Toy Exploded View

A large amount of my development time was, creating a fully working system of gears and components at all link and lock together. I wanted to make sure that my solution would function reliably, as in product like this the user should not be held back by the limitations of the product. I am very happy with my finalised solution as it allows all the parts to lock together and interact with each other well while allowing the user to experiment with the components as they see fit.

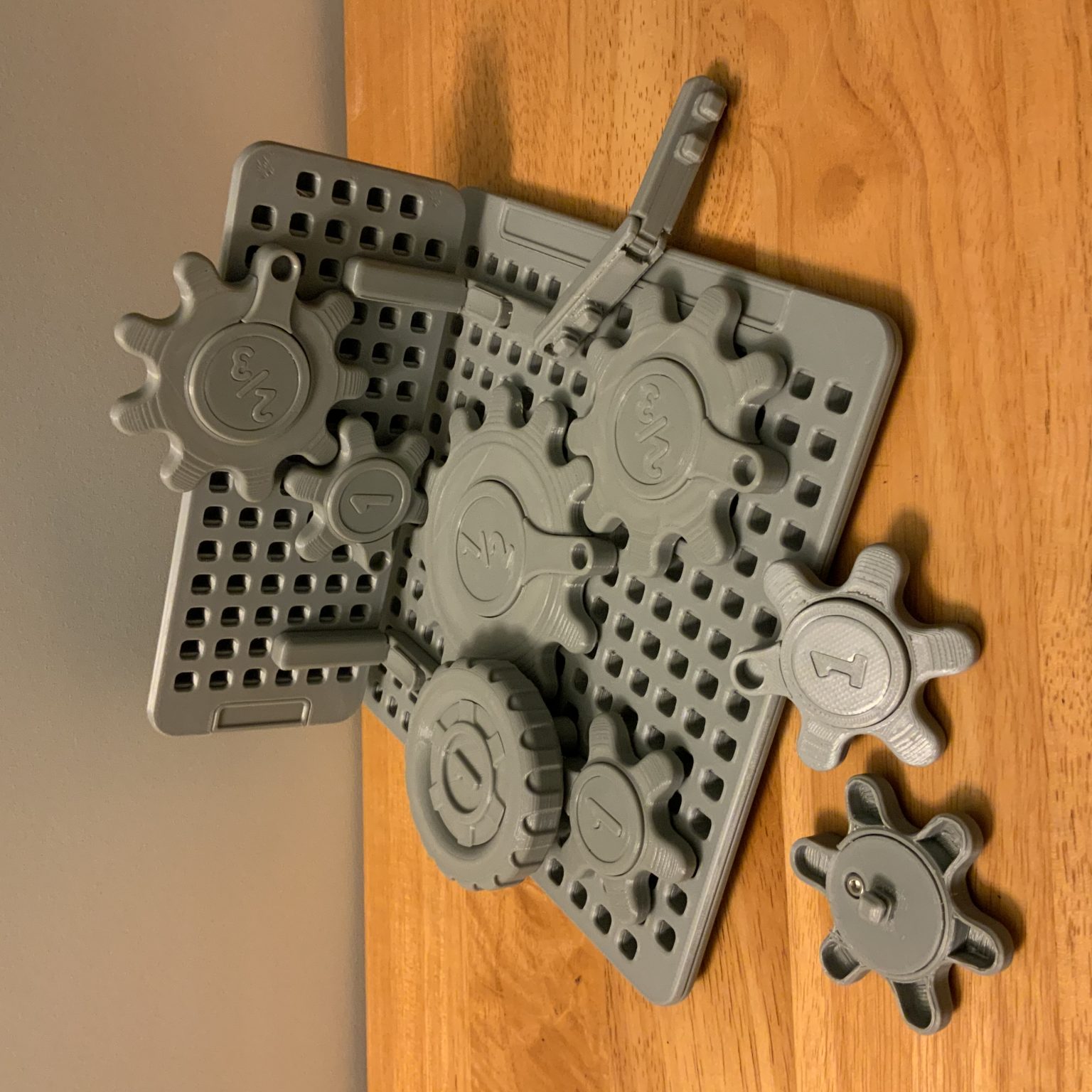

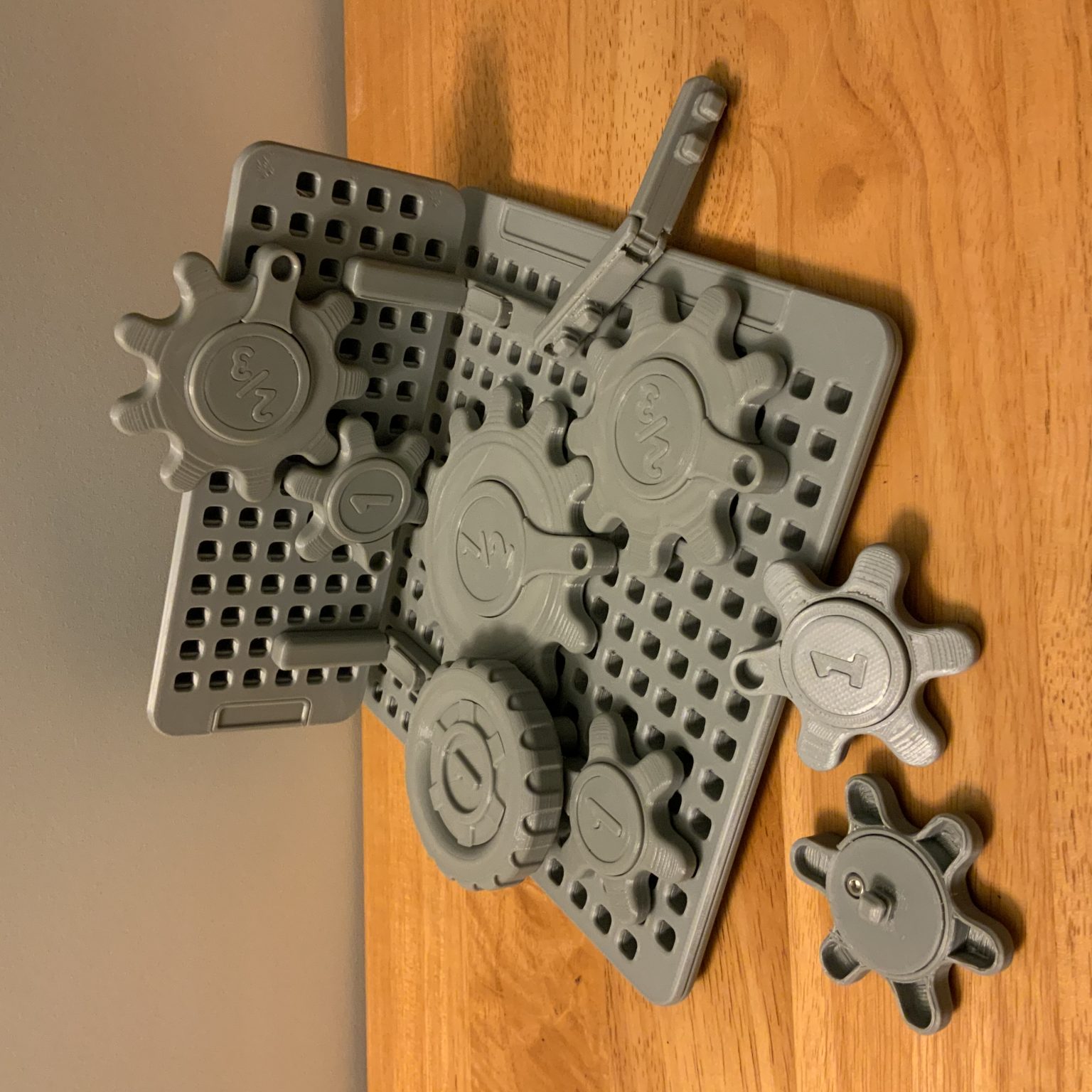

Mechanical Toy Prototype

Prototyping was a large part of my design process, more than anything else. I 3D printed a completely useable final prototype that works exactly how the product would on the market. Over the course of the project, I created countless different prototypes and versions to lead me to a finalised solution that accomplished what I had set to achieve.

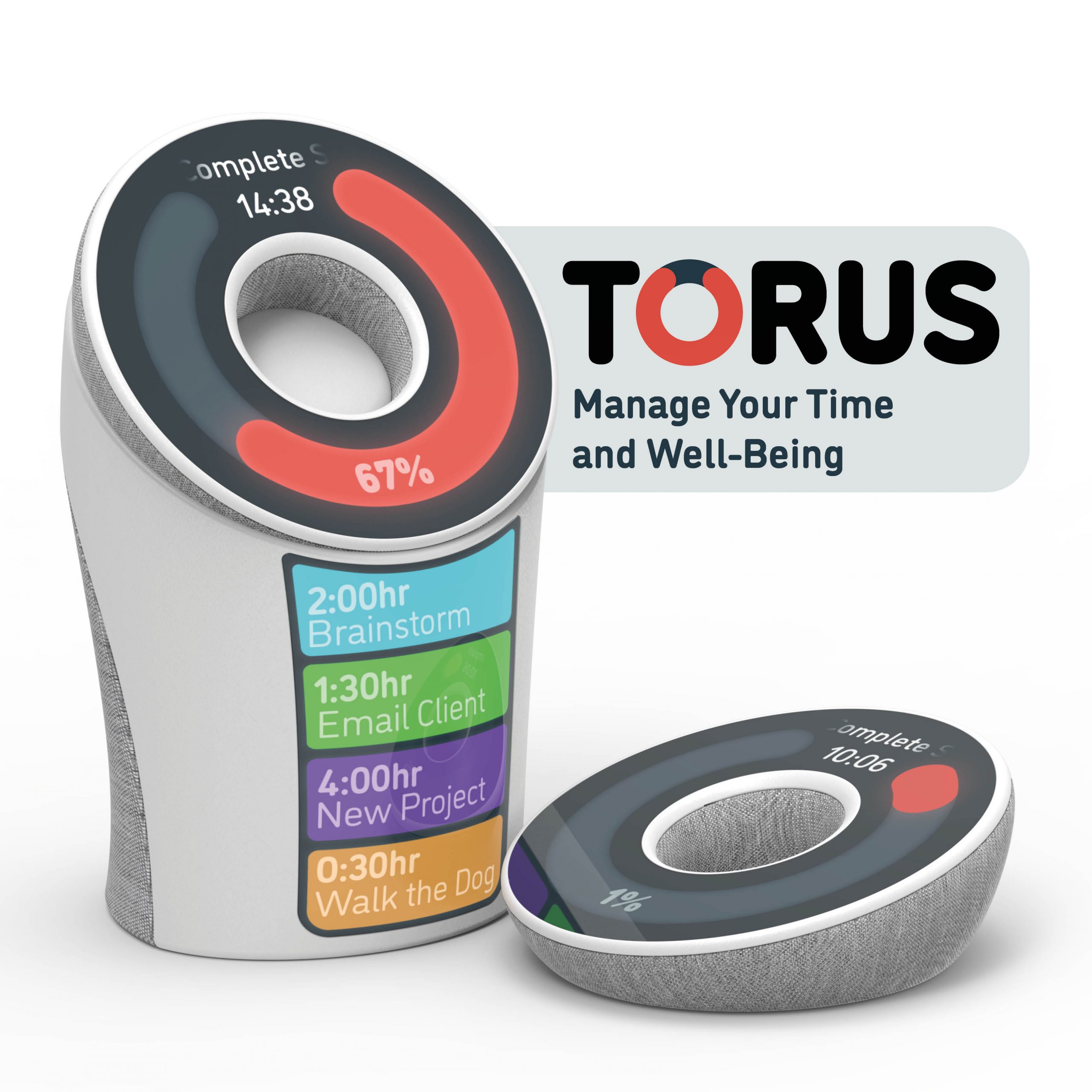

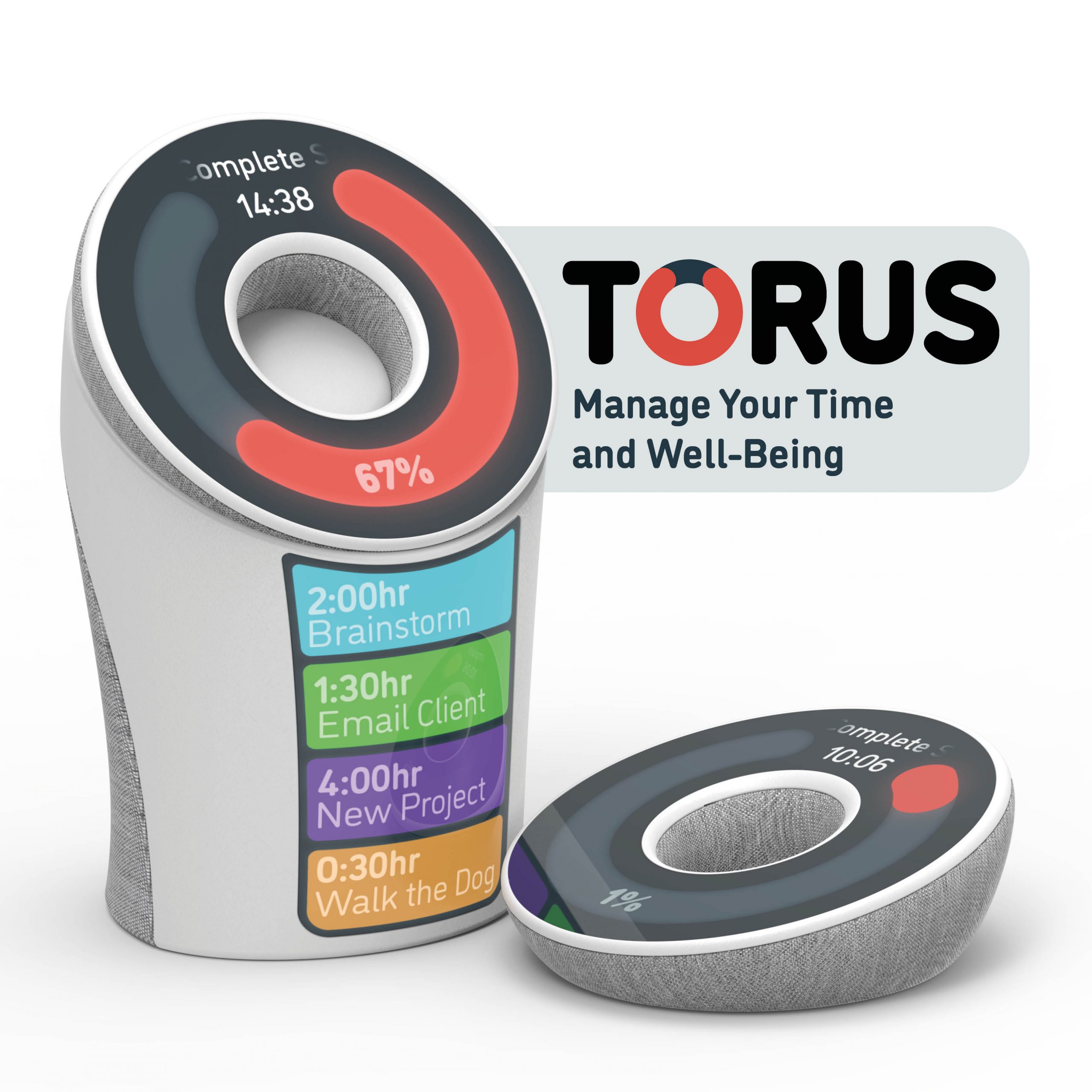

Torus: Manage Your Time and Well-Being

This project was completed in one week, following the brief "A Product that Supports the Maintenance of a Healthy, Happy Lifestyle", set by Cambridge Consultants.

Torus helps to reduce your stress and create a healthy work-life balance by organising your schedule and keep you on track while working from home.

Mechanics and Electronics Module

We were tasked as a group to create a working coffee machine using an AeroPress coffee maker. This was my design for the project that we ended up taking forward. It was designed to rotate around a central axis, meaning it can be filled from the top without ever needing to remove the AeroPress from the machine.

Dominic Storer

I am a designer that likes to get hands on with rapid prototyping and problem solving.

Final year project

A Toy that Helps Introduce Children to Mechanics

Work Experience

In 2019/20, I completed a placement year at Design By Touch Ltd. While working there I designed a variety of children's toys, both in house and for major toy manufacturers. My role mainly focused on CAD and prototyping work, proving out mechanical concepts and ideas to create functional solutions. I worked on both long, in-depth projects as well as those with tight deadlines where a rapid solution to a brief was required. I enjoyed working as part of the team, alongside other designers to create the best products and outcomes possible.