Final year project

Improving the monitoring and treatment process for respiratory illnesses such as… [Read more]

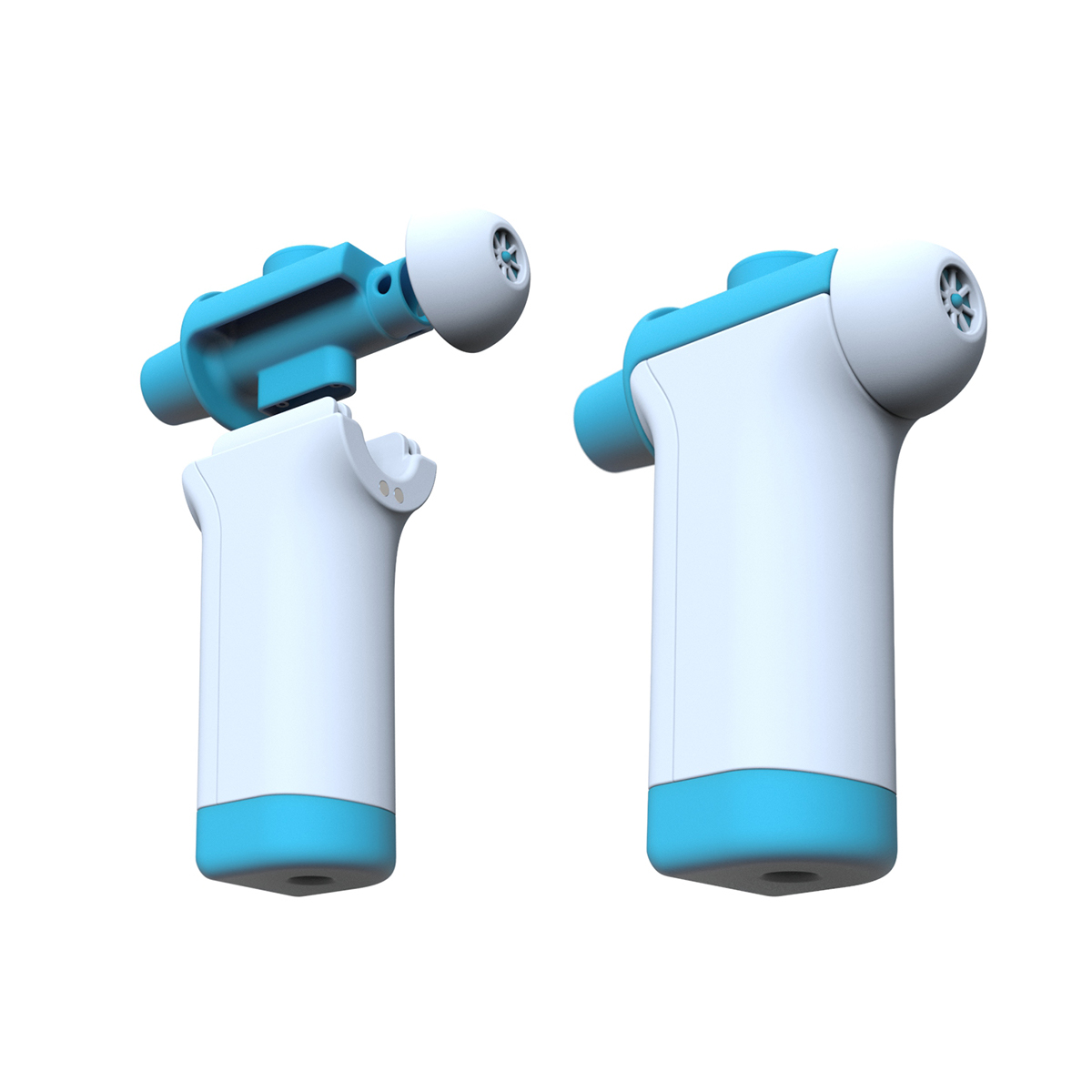

A Modular Approach to Lung Health Monitoring and Treatment

The proposed design combines multiple lung health products into one smart device that can be used at home or on the go. The device functions like a spirometer to test the health of the lungs while being compatible with attachments and new technology applications to manage symptoms and improve respiratory health.

The User Interface

To complete a spirometry test, the user inhales normally through the device and then exhales as quickly and forcefully as they can. The dot-matrix LED display lights up with the peak flow reading in L/min and the value gets stored on the cloud with other data points for the patient and their general practitioner to review.

The Components

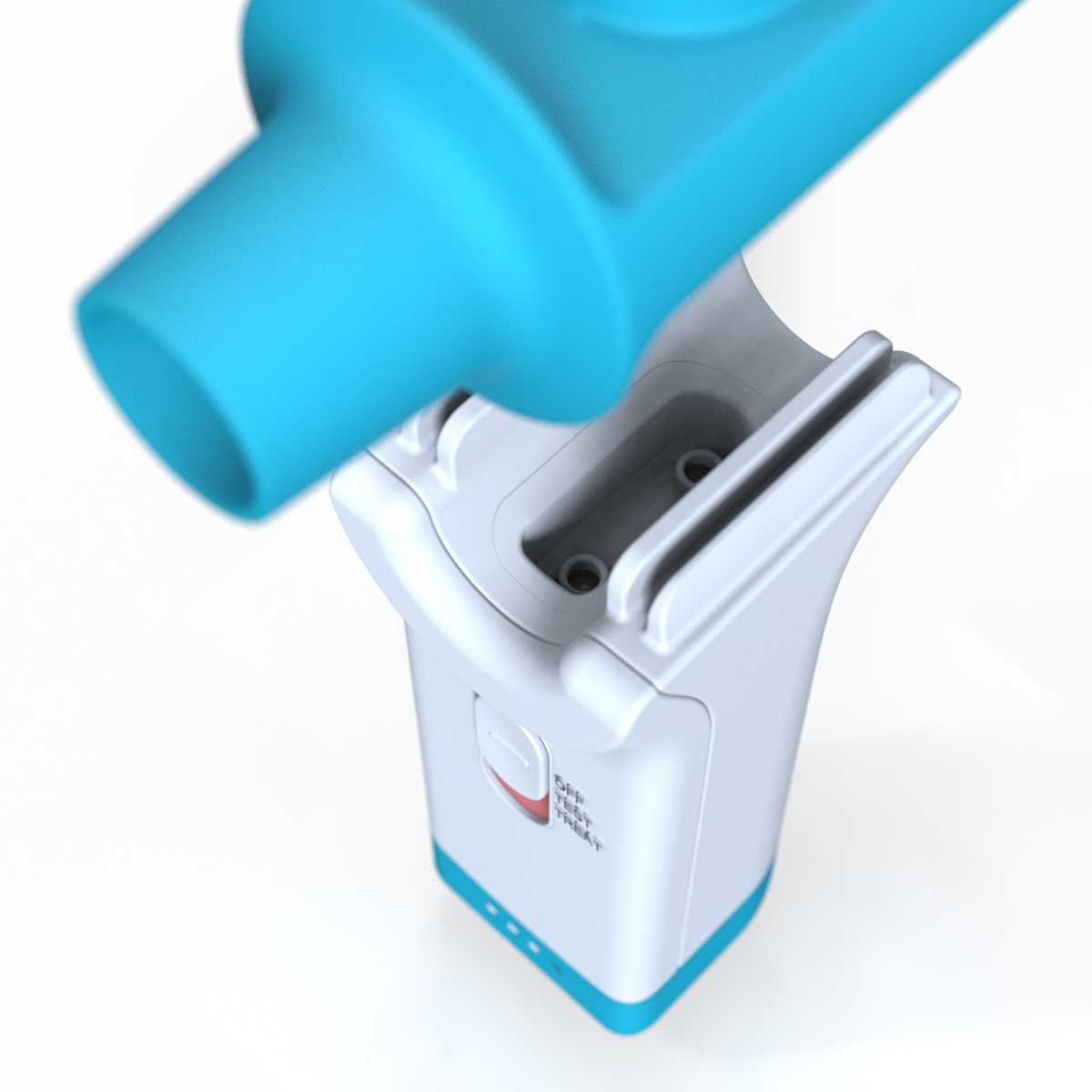

One of the biggest areas of innovation was incorporating all of the features of the mouthpiece into a single part for mass manufacture. The mouthpiece is removable for cleaning and attaches to the handle with a snap-in friction fit when the pressure sensor ports line up and create a seal.

The Attachments

The nebuliser can replace the inhale valve at the back if it decided that a patient is required to use one. The mesh technology converts a saline solution into a fine mist for a patient to inhale and manage symptoms such as shortness of breath. A patient has the option to use an anaesthetic mask with the nebuliser as the mouthpiece is compatible with the standard size fitting.

The dial can be attached to the exhale port at the top of the mouthpiece to adjust the amount of air that can pass through and create resistance while exhaling. This has been proven to have many benefits such as strengthening respiratory muscles and opening small airways deep in the lungs to improve mucus clearance.

The Treatment

The pressure sensing system inside the device allows the delivery of the mist medication from the nebuliser to be breath-actuated, making it more efficient than traditional nebulisers as no medication is lost.

The system is also capable of determining which resistance level the dial is set to based on the pressure drop inside the mouthpiece, allowing the treatment and progress to be monitored.

The Technology

The device was prototyped with a differential pressure sensor, however, a more advanced pressure sensing systems would be used for the production product to increase the breadth and accuracy of the data points. Membrane vents are attached to the sensors holes to protect the electronic components inside the handle from moisture.

Once the device is calibrated to the user, it can use AI to set inspiratory and expiratory targets. This encourages patients to take slow, deep breaths, allowing them to practise breathing techniques similarly to incentive spirometry. The device provides the user with these targets with a micro haptic feedback motor in the handle.

Alun Hopkins

I have always had a passion for technology, problem solving and innovation, and this helps me strive to achieve good design in all of the projects that I work on.

I enjoy the creative problem solving and iterative aspects of the design process the most. My strong attention to detail allows me to critically think about how existing design solutions could be improved or even look at the perceived problem from a completely different perspective entirely. Idea generation, CAD, prototyping and design for manufacture are some other examples of my core strengths. More recently I have been interested in UX design principles as I have found that it also suits my logical mindset and skillset. I am eager to learn and grow in all aspects of design, and I hope to be involved in the development of products that will have a meaningful impact on people's lives.

Final year project

Improving the monitoring and treatment process for respiratory illnesses such as COPD and asthma.

Awards

Diploma in Professional Studies

Work Experience

Working with senior designers and engineers on a variety of medical, consumer and industrial products during my placement year as a Design Intern at Design Reality was a great transition between my second and final year at university. It felt great being able to collaborate with like-minded individuals in a professional environment while learning more about design in the industry and seeing how new technology is being integrated into products. One of the most valuable takings from the experience was my improved critical thinking and thought process when approaching new challenges within both physical and digital aspects of design.