Final year project

Improving Contact Lens Hygiene [Read more]

Quick, Convenient, Clean.

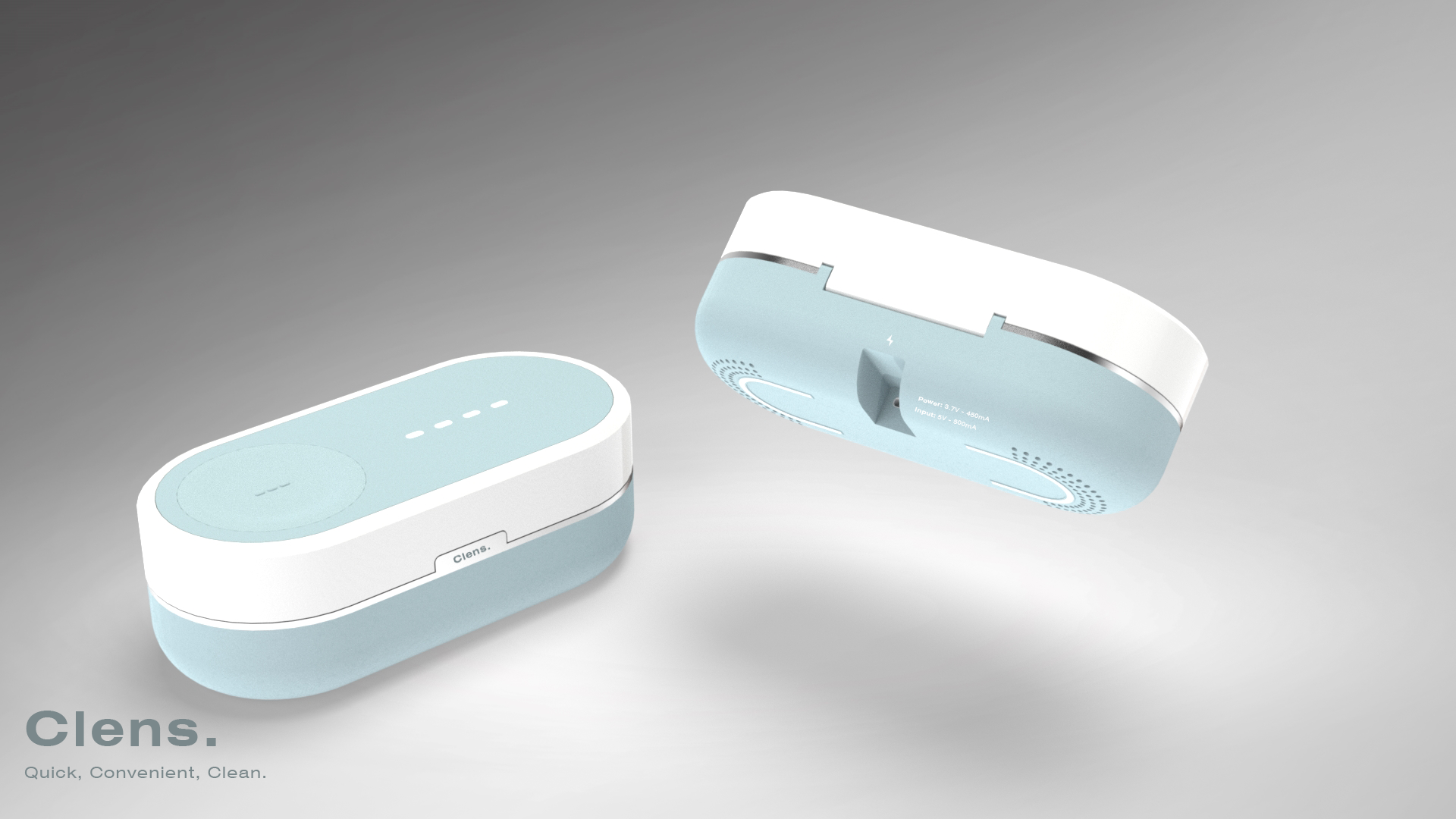

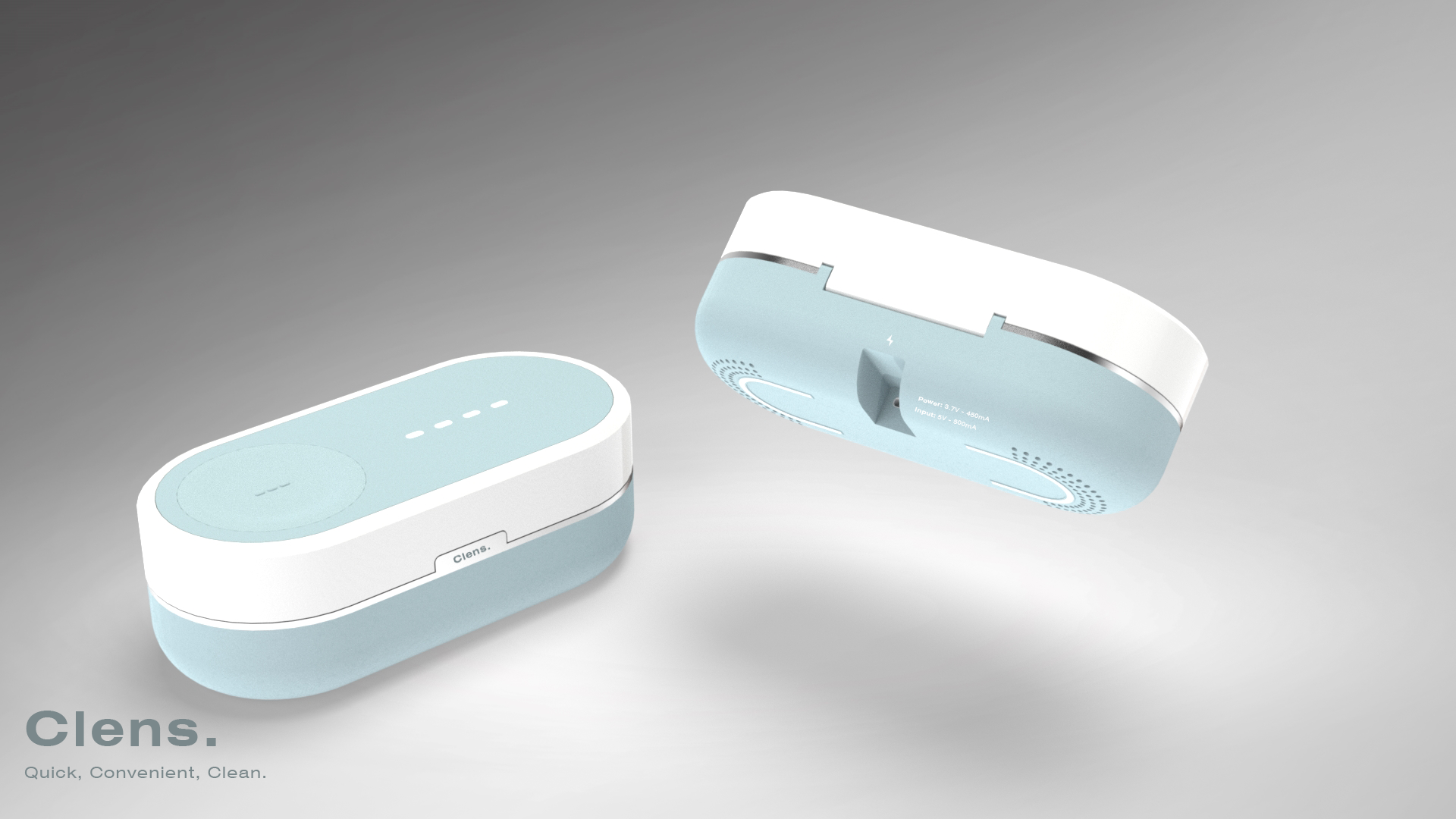

Clens is a contact lens cleaner with a focus on convenience and quality of cleanliness. The device disinfects and breakdowns proteins present on lenses through ionising plasma treatment to kill bacteria and viruses such as Acanthamoeba Keratitis. Without the need for chemical solutions, Clens requires only water and a two-minute cleaning cycle increasing convenience for the user, whether that's at home or at the office.

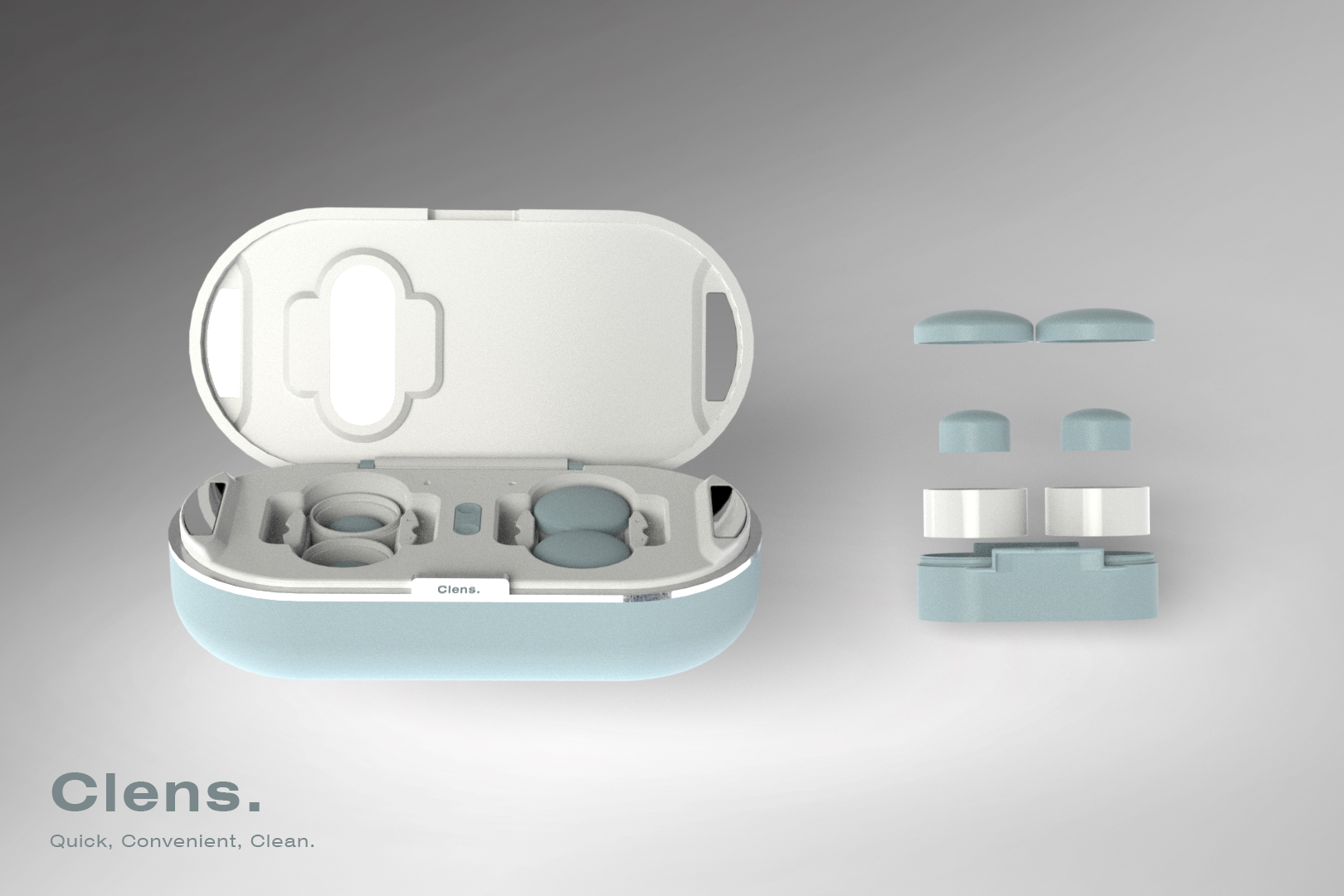

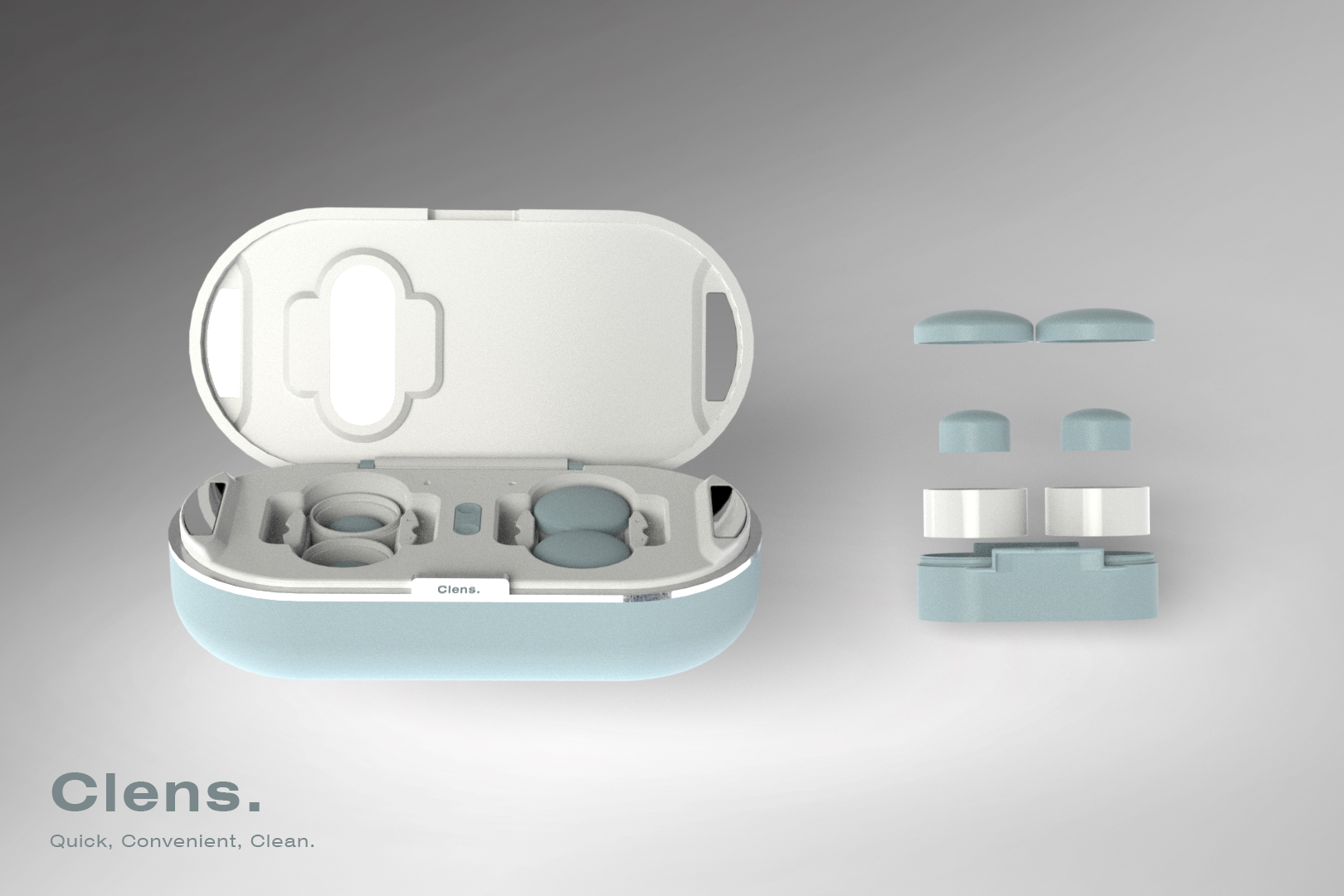

Insert Design

The design of the removable insert reduces the touchpoints between the user and the lens. The integration of a convex dome eliminates the need for the user to interact with the concave edge of a lens to correct the orientation of the lens before insertion, helping provide the clearest lens possible.

Interaction Prototyping

Clens was tested through a mixture of virtual online focus groups and interviews to provide an indication of useability. A medium-fidelity prototype was produced through 3D printing and manual milling methods. Due to restrictions, the user talked about how they would complete the actions while the researcher carried out the actions laid out to them to obtain data usually gathered through physical user testing. Each user undertook three testing stages to establish how the interactions change when knowledge of how the device works is acquired.

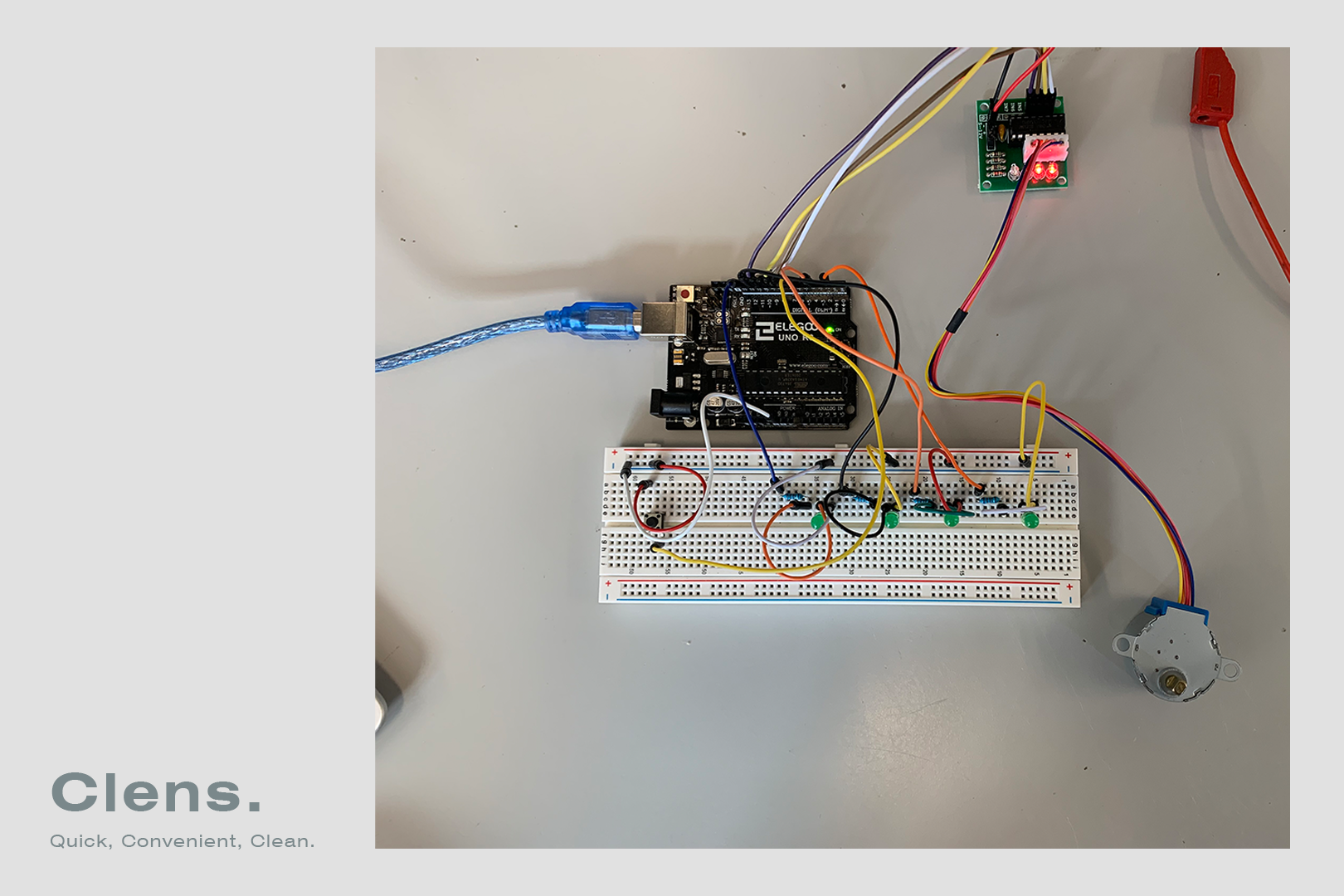

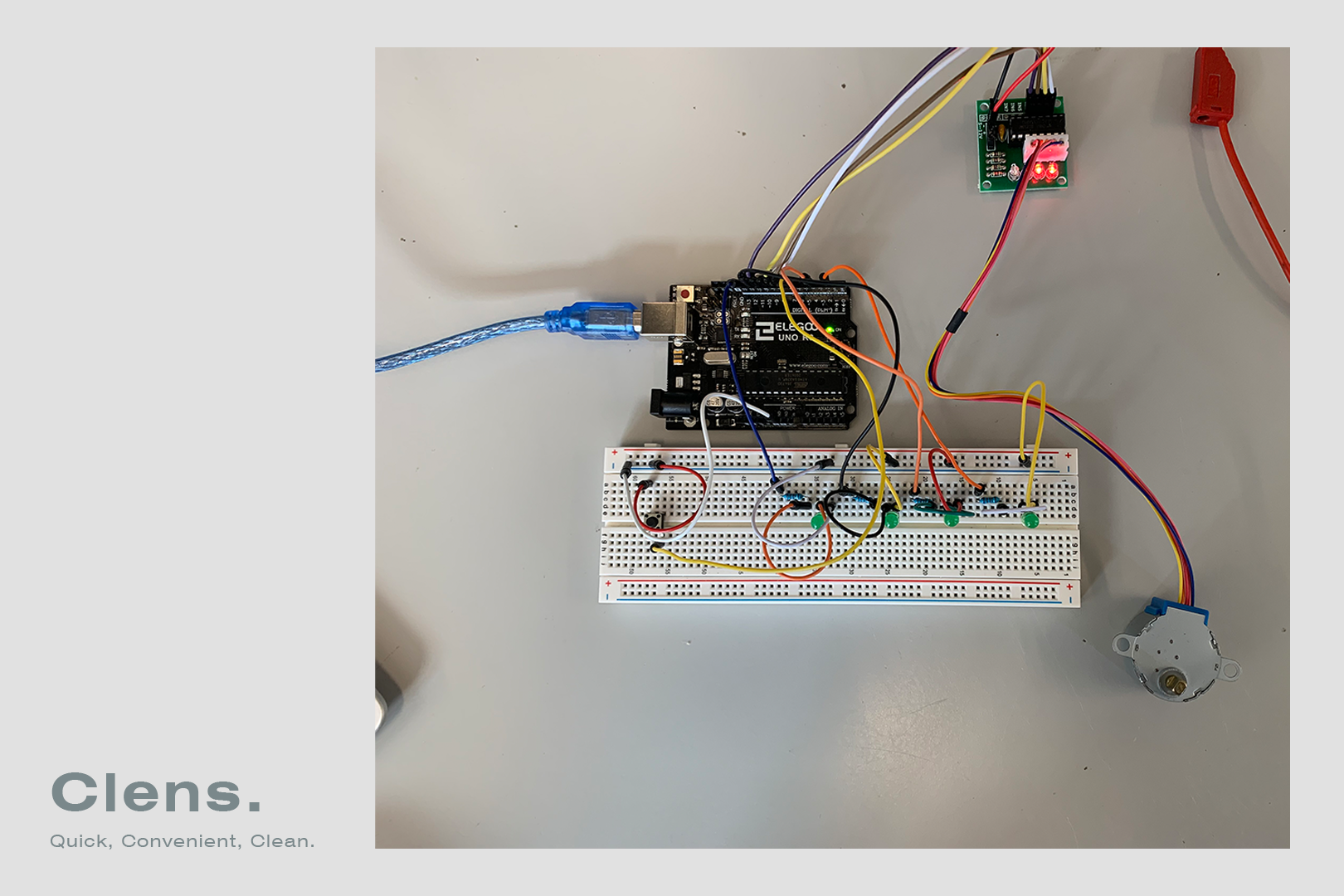

Development of Technology: Electronic Prototyping

The device works through a system of plasma technology that converts tap water into an aqueous solution on the application of a voltage through a dielectric plate sterilizing the contact lenses within the system. For the plasma technology to be effective, it was necessary for the cleaning wells to be rotated at 5rpm in order to produce significant agitation for the plasma ions to collide and ultimately clean the surface of the contact lens. Development into the agitation mechanism involved integrating a controlled degree of rotation with a signalling system to give the user indication of the cycle progress

Reducing Gender Stigma in Yoga

A home workout system focusing on the practice of yoga to assist male users in improving their flexibility and reducing repetitive chronic lower back pain while combating the gender stigma surrounding the art.

Motion Sensor: Two built-in infrared cameras to help track accuracy and progress in real-time.

Yoga Blocks: Blocks with a detachable lid to achieve two standard block sizes in one (3” x 6” x 9” and 4“ x 6” x 9”).

Yoga Mat: Integrated LED and pressure sensor technology within a laminated PVC foam mat to guide you through low to high-intensity workouts at a pace personal to your flexibility needs.

Reducing Gender Stigma in Yoga: Research Insights

Insights Gained From Research:

The expectation for males to be masculine deters users from undertaking yoga

There is an unrealistic expectation for beginner males to exhibit the same skill level as females in sessions with little work on flexibility.

The assumption that yoga is not physical enough stems from a lack of knowledge of different types of yoga.

Abbie Langley

A system encompassing plasma technology to assist in maintaining a good lens care routine for extended wear contact lens users.

Both works showcased present my ability to research a market area in a clear and concise manner to identify the main implications of the project, using secondary and primary sources in order to achieve user-focused solutions.

With strengths in research and computer-aided design, I am looking for a career within these disciplines exploring and defining user issues to define a problem.

Software Proficiency:

- Adobe Creative Cloud (Photoshop, Illustrator, Indesign, Premiere Pro)

- Solidworks and Solidworks Visualise

- Sketchbook

Final year project

Improving Contact Lens Hygiene

Awards

Starpack Student Awards 2018 Shortlist

'21 Diploma in Professional Studies

Work Experience

August 2019 - April 2020

Junior Design Engineer, Aesthetic Technology Limited

Working closely with the manufacturing department, suppliers and external contractors. Focussing on new product development and production of prototypes including market research, engineering drawings and sourcing suitable components for product development.