Final year project

Spark [Read more]

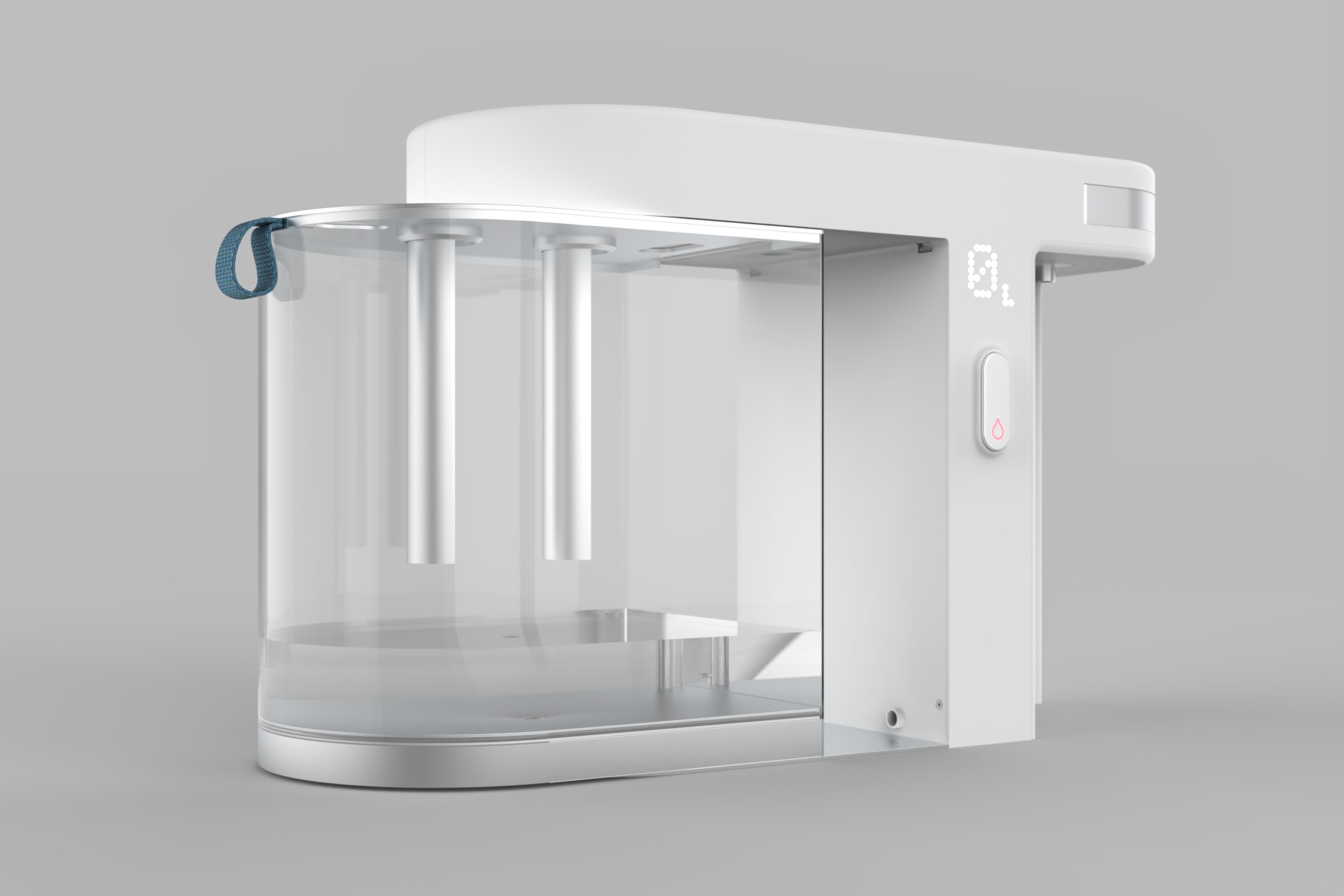

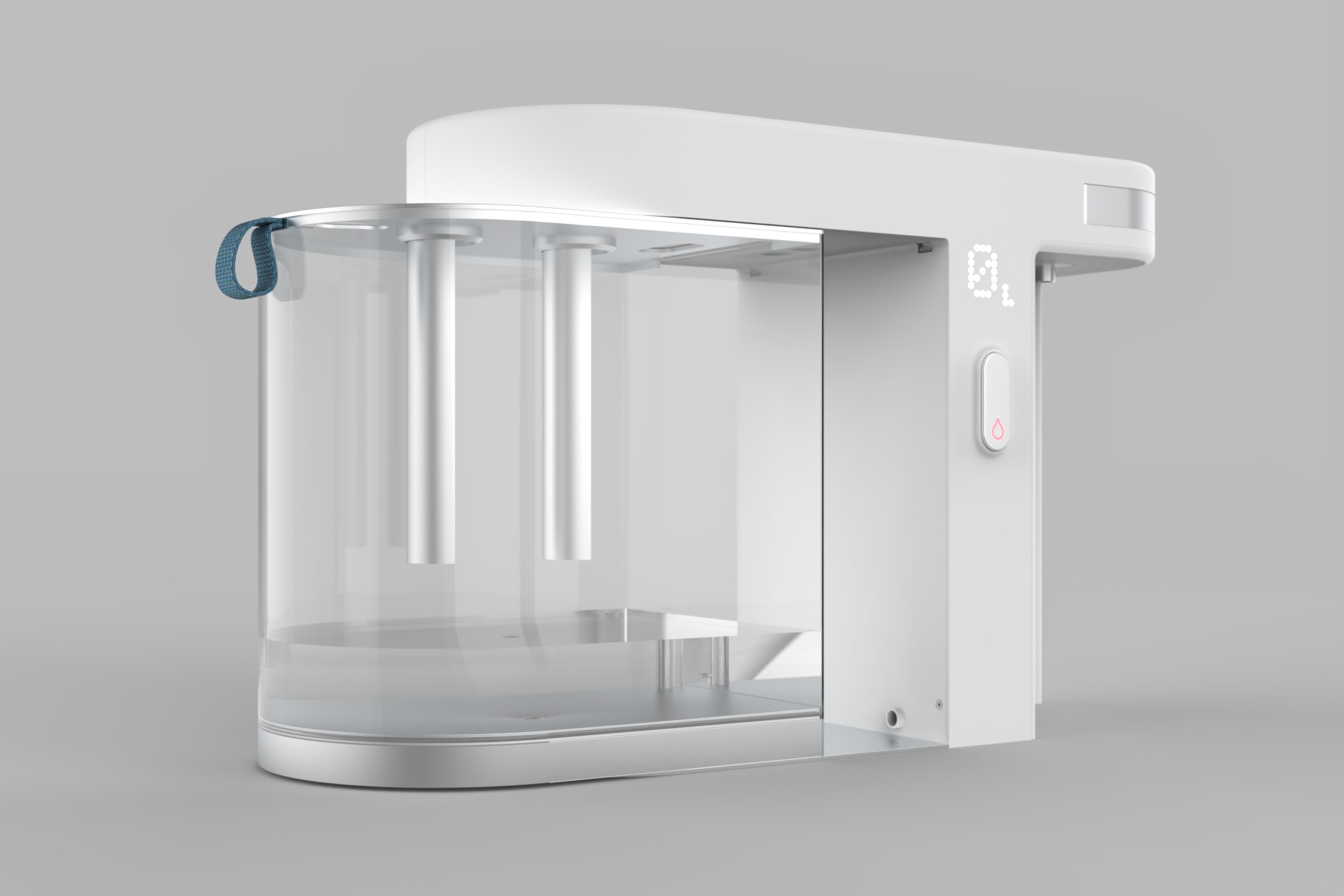

Spark - Water Purification using Electrocoagulation

Spark is a domestic water purifier that uses Electrocoagulation to separate contaminants from drinking water. Two electrode pairs pass a current through the body of water, coagulating the dissolved and suspended solids, causing them to sink to the bottom where they are drawn off in wastewater. This process removes the need for expensive and frequently replaceable filters, providing a cost-effective and sustainable alternative to conventional purification technologies such as Reverse Osmosis or Activated Carbon filtration.

LED Matrix

The volume of water in the tank is measured using an ultrasonic sensor and displayed on an LED matrix, which provides a simple, elegant, and timeless alternative to a conventional LCD. When powered off, the display disappears from sight.

Removable Tank

The water tank is magnetically attached to the main body and can be removed using the blue fabric pull tab for refilling and cleaning. Spark can be plumbed into the home water system via two solenoid valves, enabling it to fill and empty automatically.

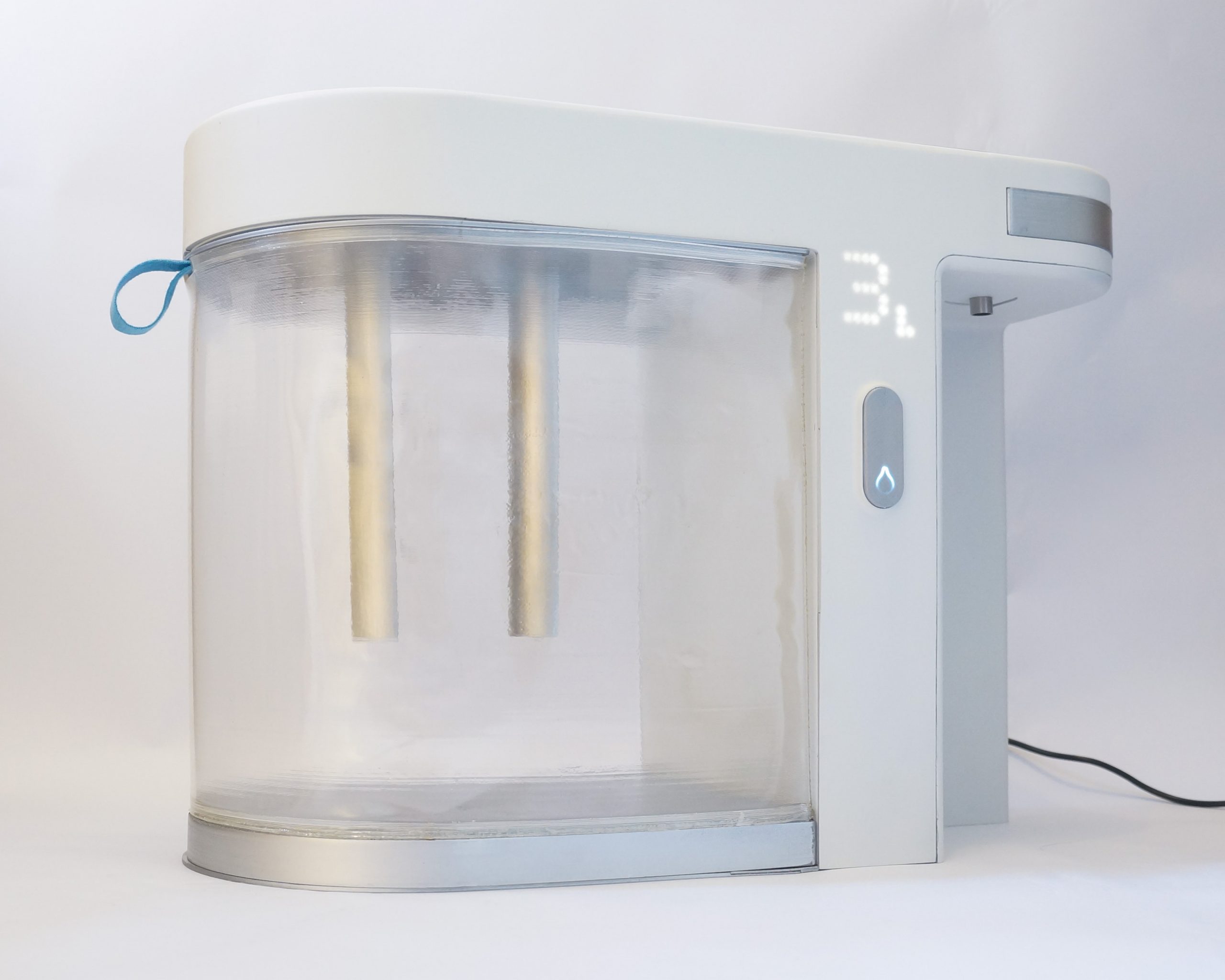

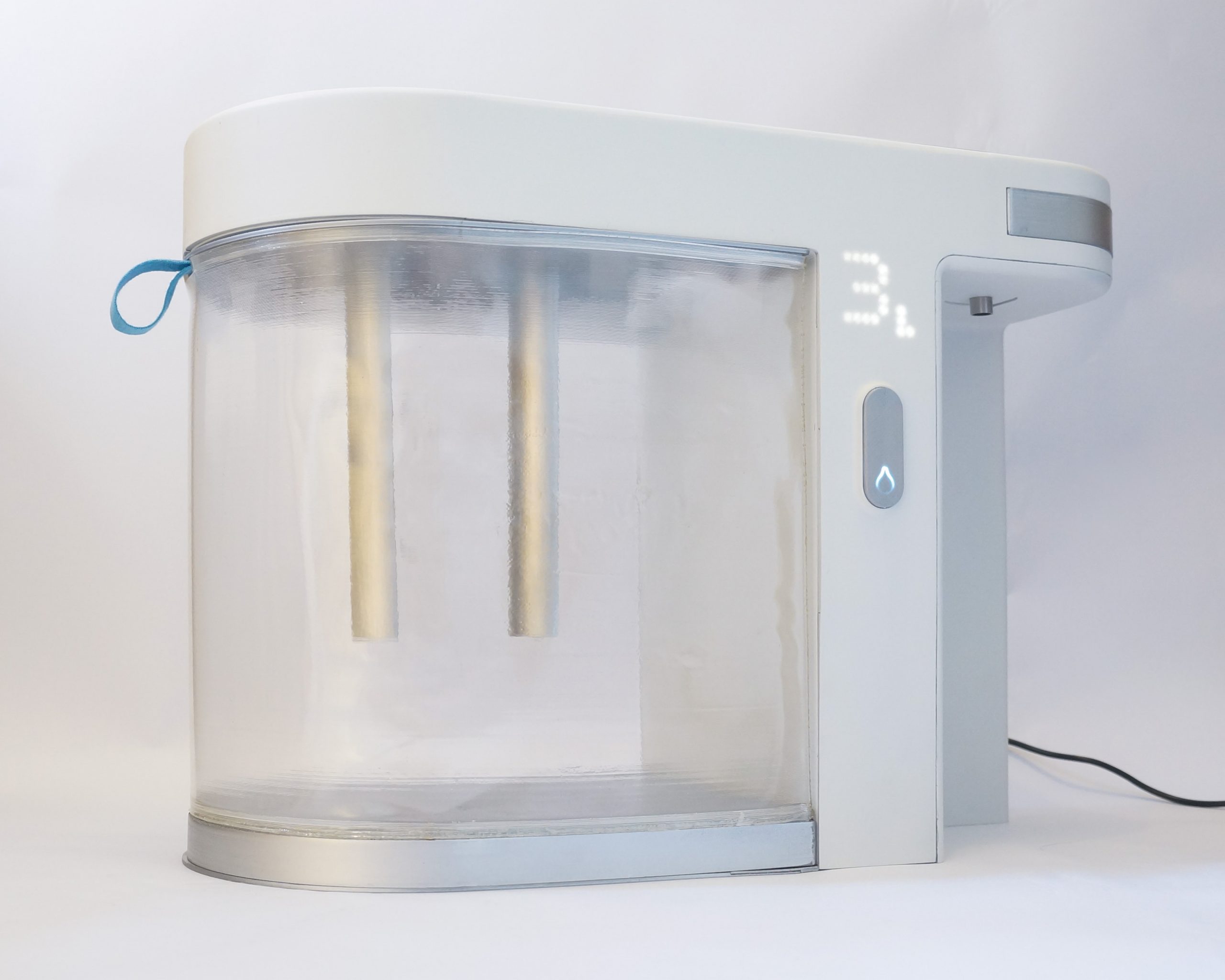

Physical Prototype

To better evaluate the aesthetics and functionality of Spark, I built a working high-fidelity model using 3D printing. The model is fully featured and includes all electronic and mechanical components needed to achieve functionality.

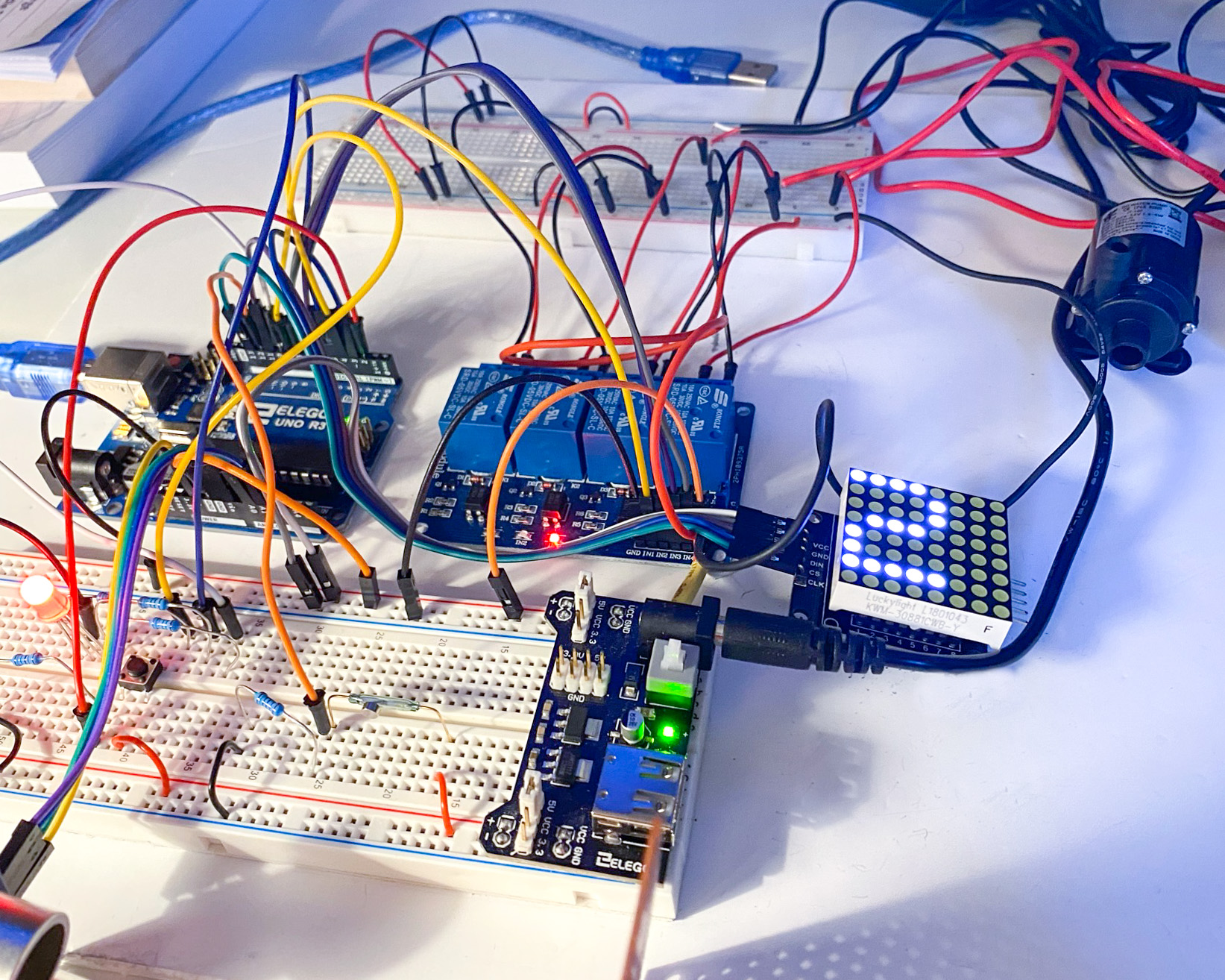

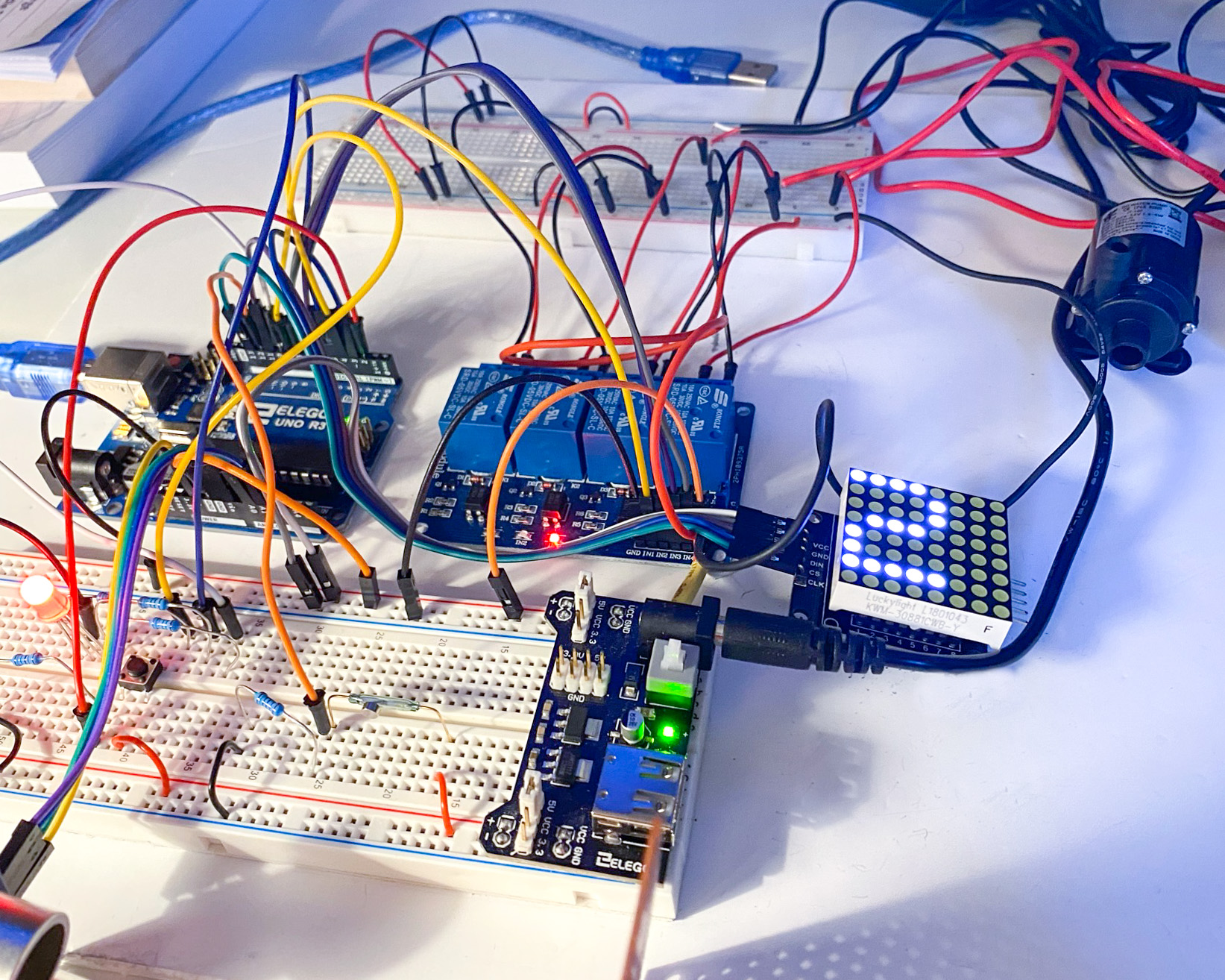

Electronics

I prototyped and iterated the Arduino-based circuitry on breadboards to test and improve the functionality. It was then transferred to soldered prototyping boards and mounted inside the 3D printed shell to make the model come to life.

Mesh Filter

A removable mesh filter was incorporated as part of the design to help remove any large impurities such as limescale. Building a high-fidelity physical prototype allowed me to test this and other features.

User Interaction

The interaction is pared down to the essentials - the user pushes the rocker switch to dispense water into a glass placed under the steel nozzle. The LED in the switch changes to red when the tank is empty or removed, and pulses during the electrocoagulation process.

Billy Hill

I’ve always been fascinated by how things work, and the meeting point between functionality and form.

I am technically-minded and enjoy solving problems. My work reflects this - I believe that a good product must always be designed with functionality and user need in mind, whilst not compromising on aesthetics.

I am interested in most design-related fields, but especially Electronics, Physical Prototyping and CAD, and am aiming for a career in the technology sector.

Final year project

Spark

Awards

'21 Diploma in Professional Studies

Work Experience

Over my placement year, I worked at Fabrikat, a steelworks engineering company. I learned a lot about the manufacturing industry, and the use of CAD to create detailed models and engineering drawings. Working in a small company allowed me to take on more responsibility in projects, and make real-world design decisions from day one.

In early 2020, I decided to start freelancing alongside my placement work. I completed over 50 projects in a 6 month period, mainly focused on CAD and product rendering for a range of clients. This was a great opportunity for me to learn about running my own business and allowed me to gain experience with client work.