Final year project

Avalanche safety respiratory airbag [Read more]

Avalanche survival respiratory airbag

A skier’s worst nightmare is being buried alive when caught in an avalanche. ARA (Avalanche Respiratory Airbag) takes avalanche airbags to the next level. The airbag provides breathable air to the user when buried by an avalanche. The red area in the graph shows how the breathable air supplied by the ARA dramatically increases the chance of survival by 40% after being buried for 30 minutes. The ARA has the capacity to provide 10 minutes worth of air over two inflation cycles.

Deployment handle

The deployment handle has revolutionary features demonstrated by a simple LED strip. The LED strip shows if the system is active, lights on; the battery level, indicated by colour and will show if the system needs a service. This will reassure not only the user but also those around them that the airbag will be deployed when needed to. This is hugely important to a range of mountaineers like skiers, snowboarders, hikers and their guides.

A thorough analysis of anthropometric data played a key role in making the handle easy for users to find and pull, even with thick gloves, to deploy the airbag.

Exploded view showing the internal components

Weight and size play a key role in the ARA design, the low profile, lightweight components make it one of the lightest avalanche airbag system on the market. A removable lithium-ion battery pack allows ease of charging. The airbag is inflated with a centrifugal fan meaning it can be deployed multiple times.

Appearance model

The design styling of ARA can be summed up as ‘Safety Chique’, using a combination of simplistic design and bold bright colours seen in safety products.

The product fits, both visually and physically, to a wide range of rucksacks meaning it has a cost advantage over other airbag systems on the market which are all built into a rucksack. ARA can be retrofitted to rucksacks already in the users’ possession.

Working prototype testing the bag inflation

Prototyping was at the core to make this concept a reality. This included a wide range of testing fan systems, bag materials, batteries, ergonomic analysis, aesthetic prototyping and user testing. “Fail fast” was the key in the process of finding the optimal design.

Tracking your recovery from home

This was a 10-day project following the brief ‘Exercise at home.'

I tackled the issue of space and making people liable for completing their exercises to help recovery when injured. The outcome was a resistance band that enables users to better comply with advice from physiotherapists by tracking, measuring, and sharing exercise data to optimise their injury recovery and prevention.

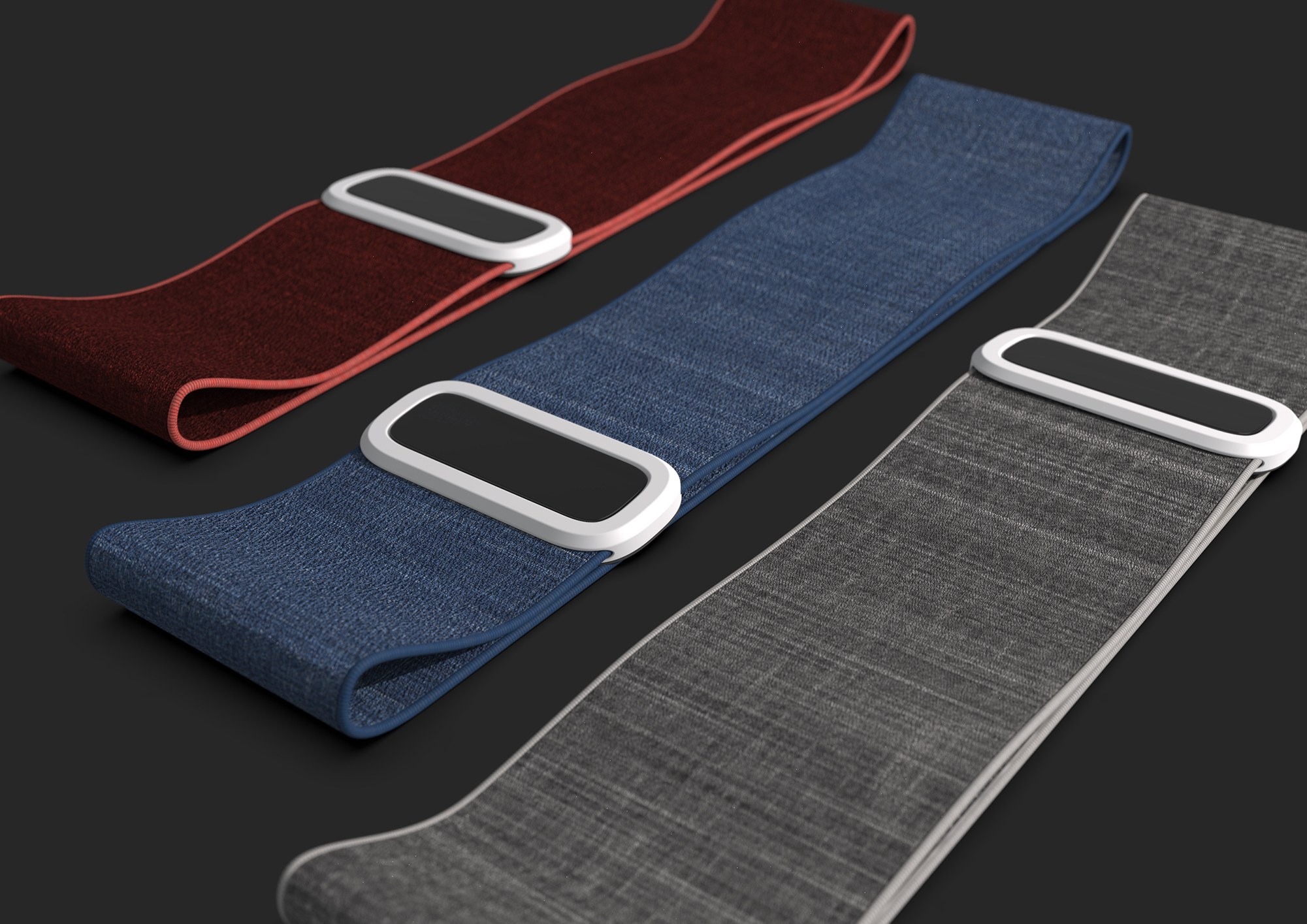

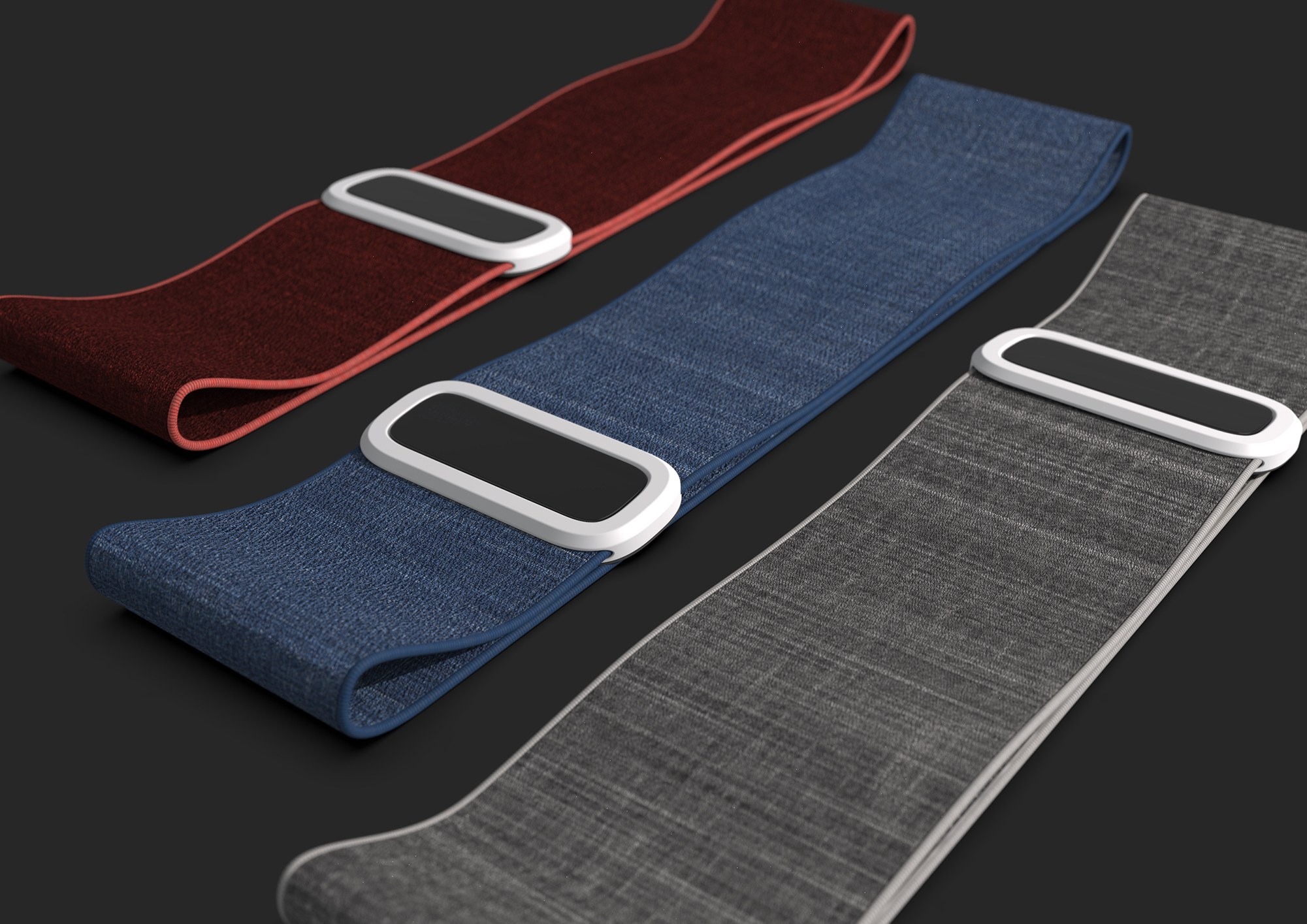

The range of resistance bands

Bands measure power output and count repetitions using an inbuilt elastic deformation sensor. A range of band strengths allows an appropriate level of difficulty for the user.

Storyboard showing the functional value of the interactive screen

The hub for the display and band can either be mounted onto a wall or function as a desktop device. When the product is not in use both the band and interactive display are charged by the hub using inductive charging. The display instructs the user what exercises to do and shares the data with their physiotherapists and doctors to improve recovery.

Tristan Howle

I am a highly driven Product designer with a passion for creating physical products which have a positive influence on people’s lives.

“People don’t buy what you do they buy why you do it”- Simon Sinek

So, why do I design? I have a strong belief that design can really make a difference in all walks of life. Passion, compassion, and care drive the design process I follow to create optimised products that have a positive effect.

My end goal when designing any product is to create a simplistic, commercially viable product that ultimately solves the user’s problem. Iteration plays a key role in my design, especially when immersed in early development and prototyping. I have learned to appreciate the value of failure during these stages as this ultimately helps me to produce not only a more successful but often more cost-effective product.

My passion for design started very young and was fuelled by a family history of ‘inventors’. My skills have developed and were built on a strong innate love for making things. Mainly thanks to my time at Loughborough design school and my internship at Ear Yoshino I now hold a wide range of skills including physical prototyping (3D printing, low fidelity modelling), CAD (Solidworks, Blender, Fusion 360, Alias Autodesk Autostudio), Sketching and Graphic design (Adobe Suite).

I am a very driven and optimistic person who thrives on new experiences. I feel interactions with team members, product users, mentors, friends and everyday contacts contribute to my creativity, development and experience as a designer. By working within a passionate design team, I intend to keep developing my design, interpersonal and other necessary skills to gain valuable knowledge. Eventually one day I strive to lead a team of my own that really makes a difference.

Final year project

Avalanche safety respiratory airbag

Awards

Diploma in Professional Studies

Arkwright Scholarship

Work Experience

EAR Yoshino is a Premium HIFI manufacturer. My role within Ear Yoshino’s design team involved redesigning existing products and designing new products. I contributed to the whole design process from initial ideation and research to manufacturing in house and externally.

My year on placement changed my perspective and design values dramatically. I learnt that design is not just a linear process, and that fast iteration is the key to creating optimised products. I was able to push myself past the limits of my design capabilities learning new skills like advanced surface modelling, 3D printing, developing my manufacturing knowledge, working within different teams, communicating my designs to different stakeholders and many more.